1. Introduction

High-current push button switches (20A and above) are critical components for heavy-duty industrial equipment. They control high-power systems—from large motors and pumps to industrial heaters and conveyor lines—relying on robust construction to handle intense electrical loads without failure.

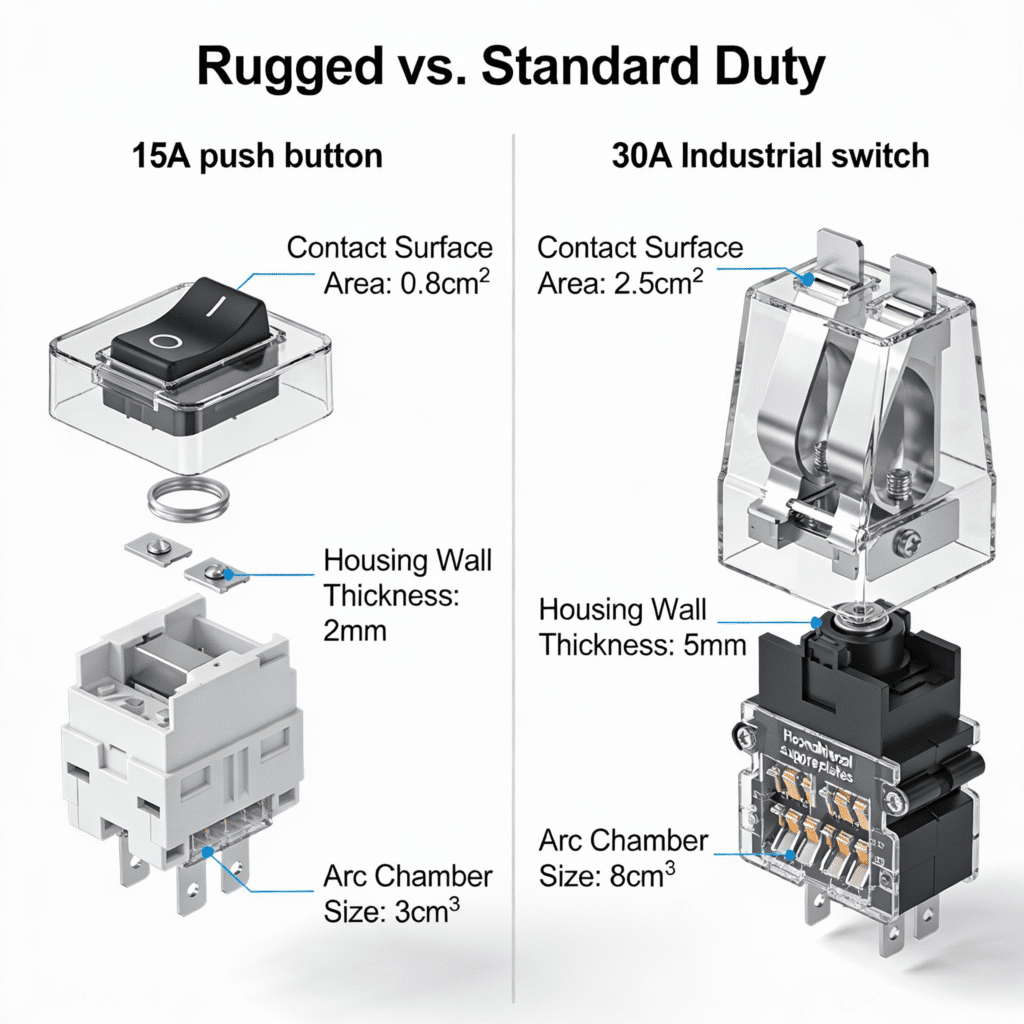

In heavy-duty environments, standard low-current push buttons (≤15A) fail quickly, leading to overheating, arcing, or even fire hazards. For example, a 10A switch used to control a 25A industrial pump will melt contacts within hours, causing unplanned downtime and safety risks. High-current switches are engineered with thick contacts, heat-resistant materials, and rugged housings to withstand continuous high-power operation.

This guide covers everything you need to know about 20A+ high-current push button switches: critical specifications, top models for heavy-duty applications, real-world case studies, step-by-step selection and installation processes, and troubleshooting tips. Whether you’re outfitting manufacturing machinery, construction equipment, or industrial processing systems, this guide ensures you choose a reliable, safe, and compliant high-current switch.

Key terms defined upfront:

- High-Current Push Button Switch: A switch rated to handle 20A or more electrical current, designed for heavy-duty industrial equipment.

- Contact Rating: The maximum current and voltage a switch can safely carry (critical for high-power applications).

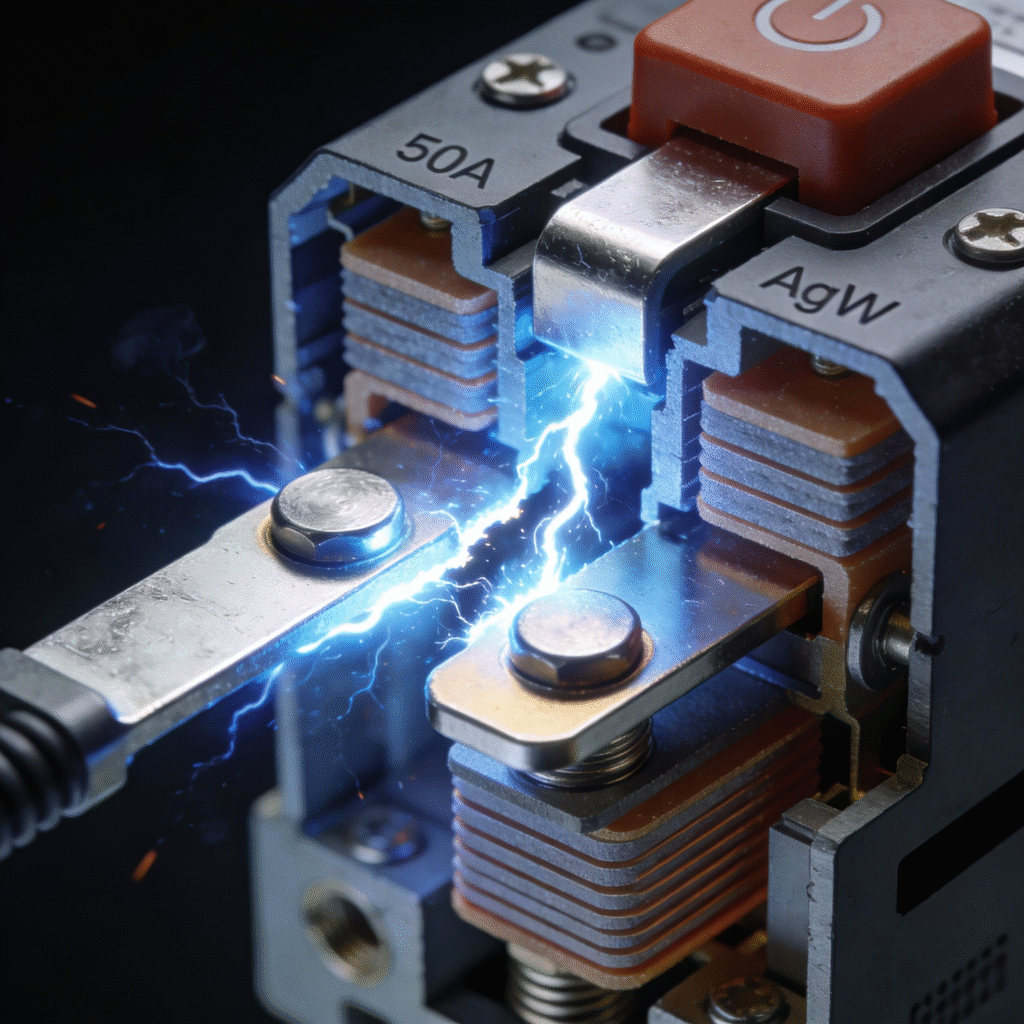

- Arc Suppression: Features (e.g., arc chutes, silver-nickel contacts) that prevent electrical arcing when switching high currents.

- Thermal Resistance: The switch’s ability to withstand heat generated by high-current flow (measured in °C).

2. Critical Specifications for 20A+ High-Current Push Buttons

2.1 Electrical Ratings

- Current Capacity: 20A–60A (standard for heavy-duty use); 60A+ for extreme applications (e.g., large industrial motors).

- Voltage Compatibility: AC (120V/240V/480V) for most industrial systems; DC (24V/48V) for battery-powered heavy equipment (e.g., forklifts).

- Contact Configuration: Single-pole single-throw (SPST) NO/NC, double-pole double-throw (DPDT) for complex circuits; silver-nickel or silver-tungsten contacts (resist arcing and corrosion).

2.2 Mechanical & Construction Features

- Housing Material: Die-cast aluminum or stainless steel (316 grade) for durability; resists impact, vibration, and harsh chemicals.

- Actuator Type: Mushroom head (large surface area for easy operation with gloves); flat head (standard use); lockable (prevents unauthorized activation).

- Arc Suppression: Built-in arc chutes or magnetic arc suppression to extinguish arcing (critical for 30A+ applications to prevent contact damage).

- IP Rating: IP65 (dust-tight, water-resistant) for general industrial use; IP67 for washdown or outdoor heavy equipment.

2.3 Safety & Compliance

- Certifications: UL, CE, CSA to meet regional electrical standards (e.g., UL 60947-5-1 for North America).

- Thermal Protection: Overload protection to shut down the switch if temperature exceeds safe limits (typically 85°C).

- Vibration Resistance: Compliant with IEC 60068-2-6 (withstands vibration from heavy machinery like industrial pumps or motors).

Case Study: Spec Mismatch FailureA construction site used a 20A high-current push button (non-arc-suppression) to control a 30A concrete mixer. Within 2 days, the switch contacts arced and welded shut, causing the mixer to run continuously. The site replaced it with a 40A switch with arc suppression (Allen-Bradley 800F series), which operated reliably for 2 years without issues.

3. Top 20A+ High-Current Push Button Switches for Heavy-Duty Use

3.1 Industrial Motor Control (20A–30A)

- Allen-Bradley 800F Series: 20A–30A, 120V AC/240V AC, silver-nickel contacts, IP65 rating. Ideal for industrial motors, conveyors, and pumps. Features arc suppression and die-cast aluminum housing.

- Siemens 3SU1600 Series: 25A, 240V AC/480V AC, lockable mushroom head, IP67 rating. Used for heavy-duty motor start/stop control in manufacturing plants.

3.2 Extreme Heavy-Duty (40A–60A)

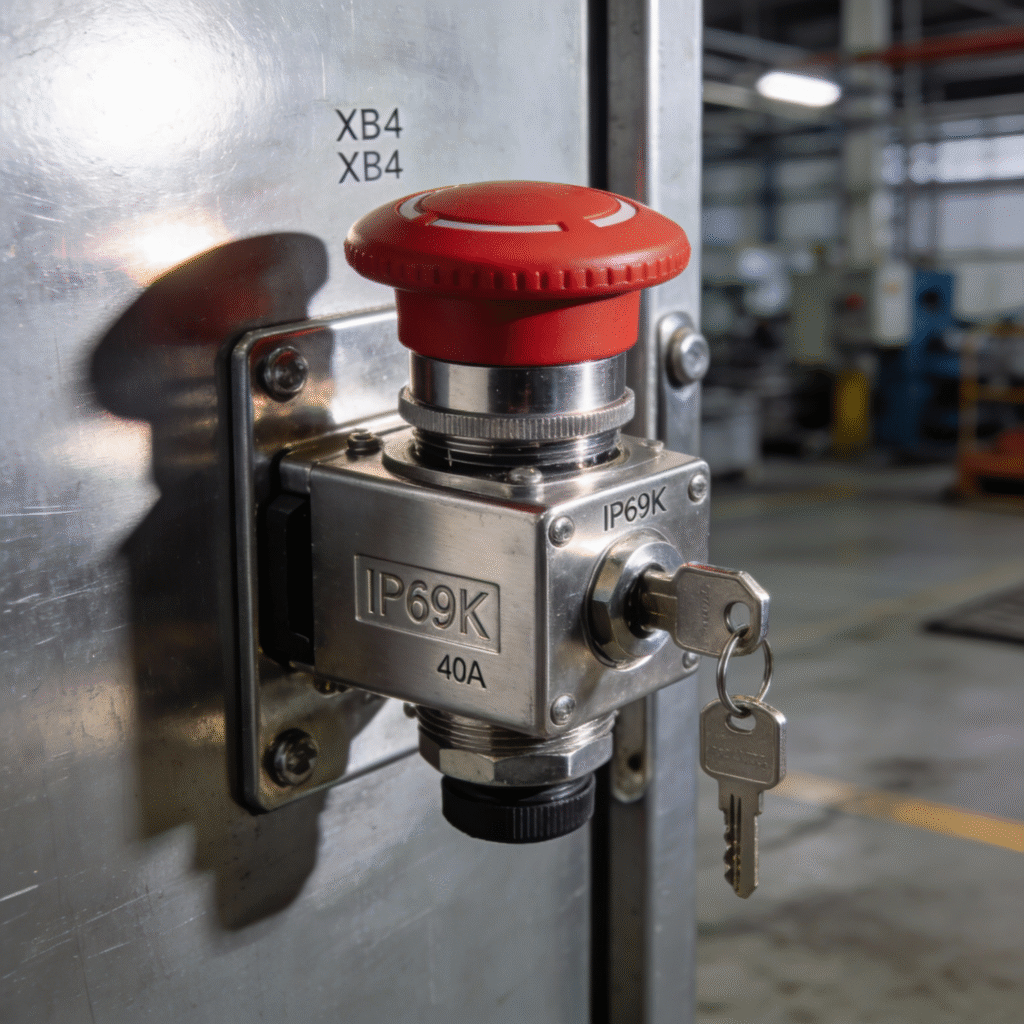

- Schneider Electric XB4 Series: 40A–60A, 480V AC, silver-tungsten contacts, IP69K rating. Resists high-pressure washdowns and extreme temperatures (-25°C to 70°C). Suitable for steel mills and chemical processing equipment.

- ABB CP1 Series: 50A, 24V DC/480V AC, double-pole contacts, vibration-resistant design. Used for battery-powered heavy equipment (e.g., forklifts) and industrial heaters.

3.3 Outdoor/Harsh Environment (20A–40A)

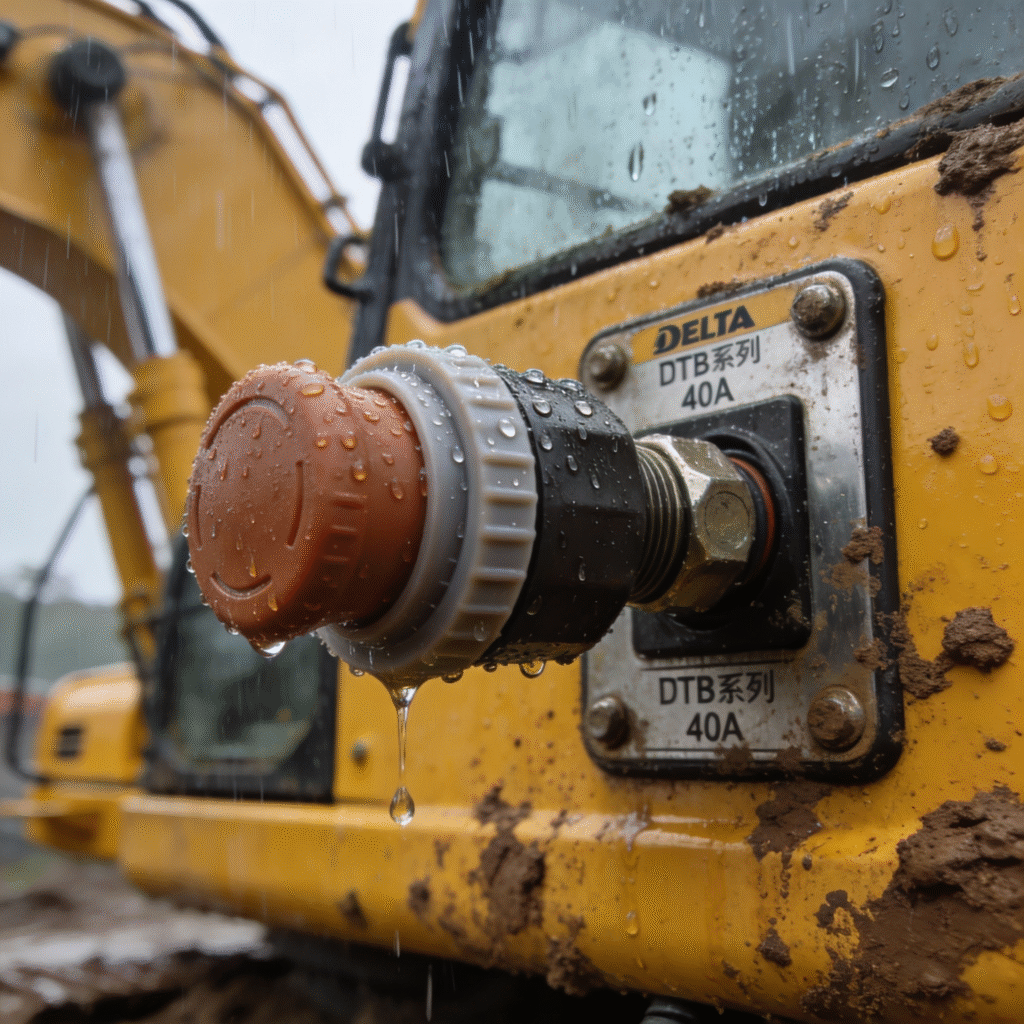

- Delta Electronics DTB Series: 20A–40A, 240V AC, 316 stainless steel housing, IP68 rating. Withstands saltwater, dust, and temperature swings. Ideal for coastal industrial facilities and construction equipment.

- IDEC HS Series: 30A, 120V AC/240V AC, impact-resistant housing, IP65 rating. Used for outdoor pumps and irrigation systems in agricultural settings.

Case Study: Steel Mill ImplementationA steel mill installed Schneider Electric XB4 60A high-current push buttons to control its rolling mill motors. The switches’ silver-tungsten contacts and arc suppression handled the 50A load, while the IP69K rating withstood high-temperature washdowns. After 3 years of operation, the switches showed no signs of wear, reducing maintenance costs by 60%.

4. Step-by-Step Selection Process

4.1 Step 1: Calculate Load Requirements

- Determine the equipment’s operating current and voltage (check the motor/pump manual).

- Select a switch with a current rating 20–30% higher than the load (e.g., a 30A load needs a 40A switch) to account for inrush current.

4.2 Step 2: Evaluate Environmental Conditions

- Indoor heavy-duty: IP65 rating, die-cast aluminum housing.

- Outdoor/harsh: IP67/IP69K rating, stainless steel housing.

- Vibration-prone (e.g., construction equipment): IEC 60068-2-6 compliant models.

4.3 Step 3: Prioritize Safety Features

- Arc suppression: Mandatory for 30A+ applications to prevent arcing.

- Lockable actuator: For safety-critical systems (e.g., emergency stop).

- Thermal protection: Reduces fire risk in continuous-operation equipment.

4.4 Step 4: Verify Mechanical Compatibility

- Mount type: 22mm/30mm panel mount (standard for control panels); surface mount (for retrofits).

- Actuator type: Mushroom head for gloved operation; flat head for standard use.

4.5 Step 5: Confirm Compliance

- Check certifications (UL, CE, CSA) for regional compliance.

- Ensure alignment with IEC 60947-5-1 (push button safety standard) and NEC Article 430 (motor control).

Example Selection Workflow: A chemical plant needs a switch for a 45A industrial heater (480V AC, outdoor installation). Selection: Schneider Electric XB4 60A switch, IP69K rating, silver-tungsten contacts, lockable mushroom head.

5. Installation & Wiring Best Practices

5.1 Pre-Installation Checks

- Verify switch current/voltage matches the load and system.

- Inspect contacts for damage (e.g., corrosion, bending) before installation.

- Ensure control panel cutouts match the switch’s mount size (22mm/30mm).

5.2 Wiring Guidelines

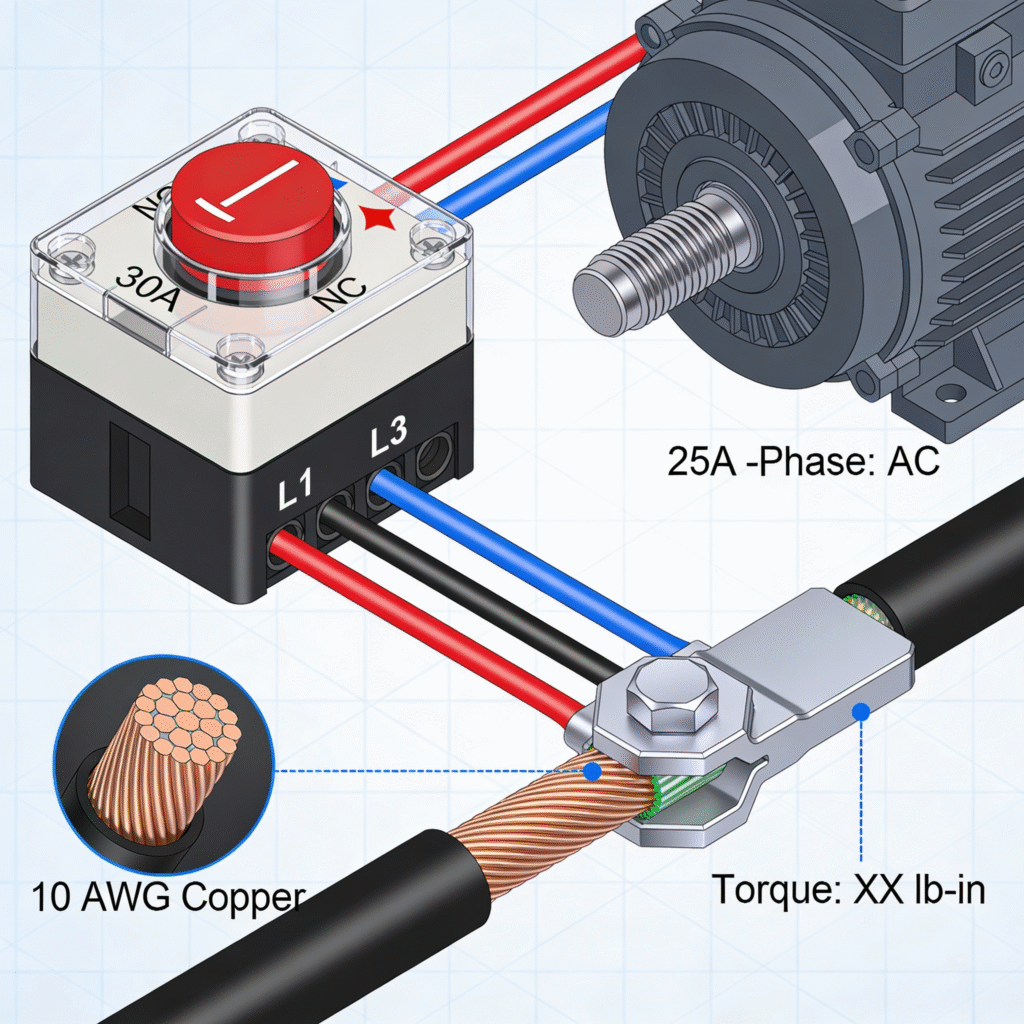

- Use copper wire of sufficient gauge (e.g., 12 AWG for 20A, 10 AWG for 30A, 8 AWG for 50A) to handle high current.

- Crimp terminals with heavy-duty connectors (avoid soldering, which can melt under high current).

- Tighten terminal screws to manufacturer specs (typically 1.5–2 N·m) to prevent loose connections and arcing.

- Install a thermal overload protector in series with the switch for additional safety.

5.3 Mounting Tips

- Secure the switch with locknuts to prevent vibration-induced loosening.

- Ensure the actuator is easily accessible (1.5–1.8m height) for operators wearing gloves.

- Seal panel cutouts with gaskets to maintain IP rating (critical for outdoor/harsh environments).

Case Study: Proper Wiring for Industrial PumpsA wastewater treatment plant installed 30A high-current switches for its 25A pumps but used undersized 14 AWG wire. The wires overheated, causing switch failure. The plant re-wired with 10 AWG copper wire and heavy-duty crimp terminals, resolving the issue and ensuring reliable operation.

6. Troubleshooting Common Issues

6.1 Switch Overheats

- Causes: Undersized wire, overloaded current, loose terminals, lack of arc suppression.

- Fixes: Upgrade to larger-gauge wire, replace with a higher-current switch, re-tighten terminals, choose a model with arc suppression.

6.2 Contact Arcing/Welding

- Causes: Inadequate arc suppression, current rating too low, DC applications without arc quenching.

- Fixes: Select a switch with arc chutes or silver-tungsten contacts, upgrade current rating, use DC-specific high-current switches.

6.3 Switch Fails to Activate

- Causes: Damaged contacts, vibration-induced loose connections, thermal overload tripping.

- Fixes: Replace contacts or the switch, re-secure terminals with locknuts, check overload protector settings.

6.4 Water/Dust Ingress

- Causes: Improper gasket installation, IP rating mismatch, loose locknuts.

- Fixes: Reinstall gaskets, replace with a higher-IP-rated switch, tighten locknuts to maintain seal.

7. Conclusion & Reference Resources

High-current push button switches (20A+) are essential for safe, reliable operation of heavy-duty industrial equipment. Selecting the right switch requires matching current/voltage to the load, prioritizing safety features like arc suppression, and adapting to environmental conditions. Proper installation—including correct wiring gauge and secure mounting—further ensures longevity and compliance.

Key takeaways:

- Choose a switch with a current rating 20–30% higher than the load to handle inrush current.

- Prioritize arc suppression (silver-nickel/silver-tungsten contacts) for 30A+ applications.

- Match IP rating to the environment (IP65 for indoor, IP67/69K for outdoor/harsh use).

- Use proper wire gauge and heavy-duty terminals to prevent overheating and arcing.

Appendix: Key Reference Resources

- IEC 60947-5-1: High-Current Push Button Safety Standard

- NEC Article 430: Motor Control Wiring Requirements

- UL 60947-5-1: North American High-Current Switch Certification

- Allen-Bradley 800F Series Technical Datasheet

- Schneider Electric XB4 High-Current Push Button Application Guide

- Siemens 3SU1600 Series Installation Manual