1. Introduction

Industrial plug sockets are the lifeline of power distribution in manufacturing, construction, and heavy-duty environments—yet industrial plug socket troubleshooting is often overlooked until failures occur. These critical components endure constant use, harsh conditions, and varying electrical loads, making them prone to three costly issues: loose connections, corrosion, and compatibility mismatches. Left unaddressed, these problems don’t just cause equipment downtime; they pose safety hazards, from electric shocks and fires to irreversible damage to expensive machinery.

This comprehensive guide dives into the root causes, symptoms, and step-by-step fixes for common industrial plug socket problems. It includes real-world case studies, tool lists, safety best practices, and preventive maintenance schedules to help you keep industrial power distribution systems running safely and efficiently. Whether you’re troubleshooting a sudden failure or implementing a proactive maintenance plan, this guide equips you with the expertise to resolve industrial plug socket issues effectively.

Key terms defined upfront:

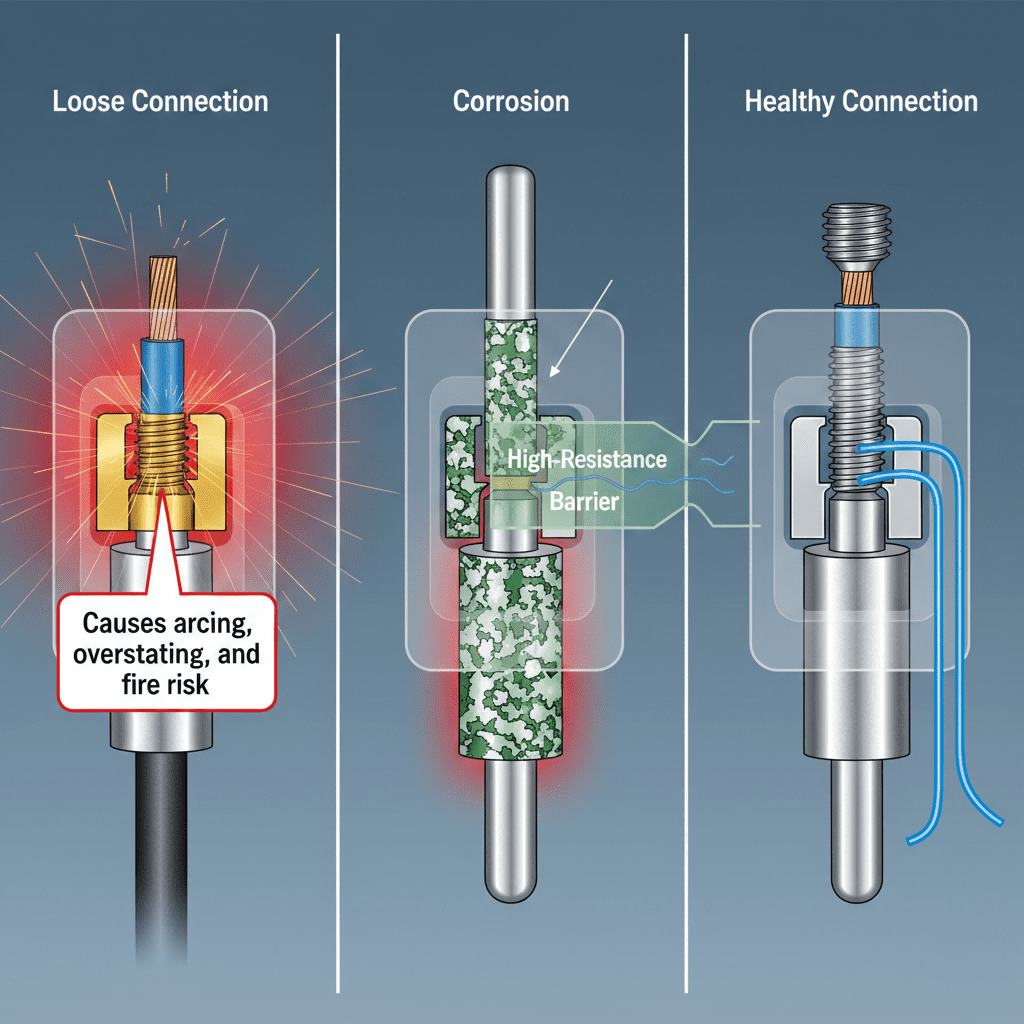

- Loose Connection: A poor electrical contact between an industrial plug and socket (or terminal) caused by vibration, improper installation, or wear—leading to arcing, overheating, and intermittent power.

- Corrosion: Degradation of metal contacts or housing in industrial plug sockets due to moisture, chemicals, or environmental exposure—impairing conductivity and causing connection failures.

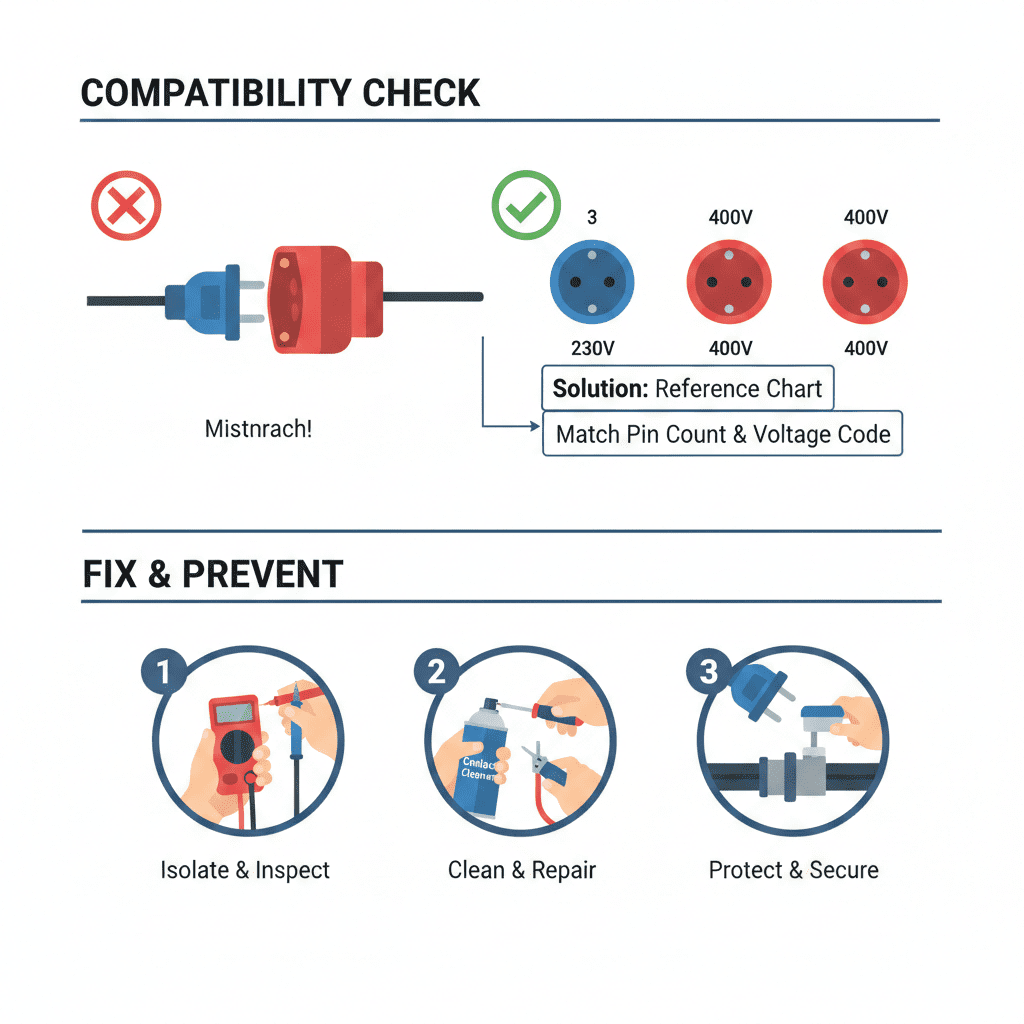

- Compatibility Mismatch: A mismatch between industrial plug/socket type, voltage, current rating, or phase configuration—preventing proper connection or causing electrical failures.

- Arcing: Electrical discharge between contacts of industrial plug sockets due to poor connection—generates heat and can damage contacts or start fires.

2. Industrial Plug Socket Troubleshooting: Loose Connections

Loose connections are the most common issue with industrial plug sockets, often caused by vibration, improper installation, or repeated plugging/unplugging. Left unaddressed, they lead to arcing, overheating, and equipment damage—making them a top priority in industrial plug socket troubleshooting.

2.1 Root Causes of Loose Industrial Plug Socket Connections

- Vibration: Industrial machinery (e.g., pumps, conveyors) generates constant vibration that loosens plug-socket connections or terminal screws in industrial plug sockets.

- Improper Installation: Under-tightened terminal screws, inadequate plug insertion, or poorly crimped wires in industrial plug socket setups.

- Wear & Tear: Repeated plugging/unplugging wears down contact springs in industrial plug sockets, reducing tension and creating gaps.

- Thermal Expansion: Temperature fluctuations (e.g., near industrial furnaces) cause metal components in industrial plug sockets to expand and contract, loosening connections.

2.2 Key Symptoms of Loose Industrial Plug Socket Connections

- Intermittent power to equipment (e.g., tools cutting out, motors stalling) connected to industrial plug sockets.

- Visible arcing (sparks) when plugging into or using industrial plug sockets.

- Overheating of industrial plug socket housing (hot to the touch).

- Burn marks or discoloration on contacts or wires of industrial plug sockets.

- Tripped circuit breakers or blown fuses linked to industrial plug socket use.

2.3 Step-by-Step Fixes for Loose Industrial Plug Socket Connections

1: Tighten Terminal Screws in Industrial Plug Sockets

- Turn off power and lock out/tag out the circuit to prevent electric shock when working on industrial plug sockets.

- Disconnect the industrial plug from the socket and remove the plug’s housing (if accessing internal terminals).

- Use a torque screwdriver to tighten terminal screws to the manufacturer’s specification (typically 0.8–1.5 N·m)—avoid over-tightening, which can strip threads or damage industrial plug socket terminals.

- Reassemble the industrial plug and reconnect to the socket; test equipment for stable power.

2: Repair or Replace Worn Industrial Plug Sockets

- Inspect industrial plug contacts for bent prongs, worn springs, or damage—replace the plug if contacts are deformed.

- Check industrial socket contacts for wear or loss of tension (use a multimeter to test continuity when the plug is inserted).

- Replace industrial sockets with worn contacts (e.g., loose prongs, burned surfaces) to restore proper connection.

3: Secure Industrial Plug Socket Connections Against Vibration

- Use vibration-resistant industrial plug sockets with locking mechanisms (e.g., twist-lock, screw-lock) to prevent loosening.

- Install rubber vibration dampeners around industrial socket boxes or mount them on stable surfaces to reduce movement.

- Use cable ties to secure power cords away from vibrating machinery, preventing tugging on the industrial plug.

2.4 Case Study: Loose Industrial Plug Socket Connections in a Manufacturing Plant

- Challenge: A car assembly plant experienced frequent downtime with robotic welding arms due to intermittent power. Inspections revealed loose terminal screws in the Type A industrial plug sockets, caused by vibration from the welding equipment.

- Solution: Maintenance teams tightened all terminal screws to 1.2 N·m (Siemens’ specified torque) and replaced 15% of industrial plugs with worn contact springs. They also installed twist-lock industrial plug sockets (Allen-Bradley 800F Series) for critical welding stations to resist vibration.

- Results: Equipment downtime reduced by 75%, and arcing incidents eliminated. The plant implemented a monthly torque-check schedule for industrial plug sockets in high-vibration areas.

3. Industrial Plug Socket Troubleshooting: Corrosion

Corrosion is a persistent issue in industrial environments with moisture, chemicals, or salt air—directly impacting the performance of industrial plug sockets. It degrades contacts, blocks electrical flow, and can lead to complete connection failure, requiring targeted industrial plug socket troubleshooting.

3.1 Root Causes of Corrosion in Industrial Plug Sockets

- Moisture Exposure: Rain, washdowns, or high humidity (e.g., food processing plants, coastal facilities) affecting industrial plug sockets.

- Chemical Exposure: Oils, solvents, or corrosive cleaners (e.g., automotive workshops, chemical plants) damaging industrial plug socket components.

- Salt Air: Coastal or marine industrial environments (e.g., ports, offshore rigs) accelerating metal degradation in industrial plug sockets.

- Poor Ventilation: Stagnant air traps moisture, promoting corrosion on contacts and housing of industrial plug sockets.

3.2 Key Symptoms of Corroded Industrial Plug Sockets

- Green/white rust on metal contacts or plug prongs of industrial plug sockets.

- Increased resistance (measured via multimeter) leading to overheating in industrial plug sockets.

- Intermittent power or complete connection failure with industrial plug sockets.

- Sticky or difficult plug insertion (corrosion buildup blocking movement in industrial plug sockets).

- Discolored or degraded plastic housing (sign of prolonged moisture exposure in industrial plug sockets).

3.3 Step-by-Step Fixes for Corroded Industrial Plug Sockets

1: Clean Corroded Contacts in Industrial Plug Sockets

- Disconnect power and lock out/tag out; remove the industrial plug from the socket.

- Use a dry wire brush or abrasive pad to gently scrape corrosion from industrial plug socket contacts (avoid excessive force to prevent damage).

- Apply a small amount of electrical contact cleaner (e.g., isopropyl alcohol) to a cloth and wipe industrial plug socket contacts clean—ensure no residue remains.

- For severe corrosion, use a contact restoration paste (e.g., silver-based paste) to improve conductivity in industrial plug sockets.

- Reconnect the industrial plug and test continuity with a multimeter; replace if conductivity is still poor.

2: Replace Corroded Industrial Plug Socket Components

- If contacts are pitted, cracked, or heavily corroded (beyond cleaning), replace the industrial plug, socket, or both.

- Choose corrosion-resistant industrial plug socket replacements (e.g., 316 stainless steel contacts, nickel-plated prongs) for harsh environments.

- For marine/coastal applications, select industrial plug sockets with specialized anti-corrosion coatings (e.g., Delta Electronics DTB Series).

3: Prevent Future Corrosion in Industrial Plug Sockets

- Upgrade to IP65+ rated industrial plug sockets to seal out moisture and debris.

- Use socket covers or caps for unused industrial plug sockets to prevent moisture ingress.

- Improve ventilation in enclosed areas (e.g., control panels) to reduce humidity around industrial plug sockets.

- Apply a thin layer of corrosion-inhibiting spray to industrial plug socket contacts (compatible with electrical components) for long-term protection.

3.4 Case Study: Corrosion in Coastal Industrial Plug Sockets

- Challenge: A seafood processing plant in Florida faced frequent socket failures due to salt air and daily washdowns. Corrosion on Type I industrial plug sockets caused short circuits and equipment downtime.

- Solution: The plant replaced standard sockets with 316 stainless steel IP69K-rated industrial plug sockets (ABB CP1 Series) with Viton gaskets. Maintenance teams implemented a biweekly cleaning schedule using contact cleaner and corrosion inhibitor on industrial plug sockets. Unused sockets were fitted with waterproof caps.

- Results: Industrial plug socket replacement frequency dropped from monthly to annually, reducing maintenance costs by 90%. No corrosion-related failures were reported after the upgrade.

4. Industrial Plug Socket Troubleshooting: Compatibility Mismatches

Compatibility issues arise when industrial plug sockets don’t align in type, voltage, current rating, or phase configuration—preventing connection or causing electrical damage. This requires focused industrial plug socket troubleshooting to resolve mismatches.

4.1 Root Causes of Industrial Plug Socket Compatibility Mismatches

- Plug/Socket Type Mismatch: Using regionally incompatible industrial plug sockets (e.g., Type A plug with Type I socket, CEE plug with NEMA socket).

- Voltage Mismatch: Connecting a 230V device to a 120V industrial socket (or vice versa) due to incorrect equipment sourcing.

- Current Rating Mismatch: Using a low-current industrial plug socket (e.g., 16A) for high-current equipment (e.g., 32A) leading to overheating.

- Phase Configuration Mismatch: Connecting a three-phase industrial plug to a single-phase socket (or incorrect phase wiring).

4.2 Key Symptoms of Industrial Plug Socket Compatibility Mismatches

- Industrial plug cannot be inserted into the socket (physical incompatibility).

- Equipment fails to power on or operates at reduced capacity with industrial plug sockets.

- Overheating, burning smells, or blown fuses immediately after connecting to industrial plug sockets.

- Damage to equipment circuitry (e.g., fried motors, control panels) from industrial plug socket voltage/current mismatch.

- Tripped RCDs (Residual Current Devices) due to industrial plug socket phase wiring errors.

4.3 Step-by-Step Fixes for Industrial Plug Socket Compatibility Mismatches

1: Resolve Industrial Plug Socket Type Mismatch

- Identify the industrial plug and socket types (e.g., Type A, Type I, CEE) using equipment manuals or visual inspection.

- Short-Term: Use industrial-grade adapters (rated for the equipment’s current/voltage) for temporary industrial plug socket compatibility (e.g., Type A-to-Type I adapter for 15A loads).

- Long-Term: Retrofit industrial plug sockets to match regional standards (e.g., replace Type C plugs with Type A for North American facilities) or install dual-standard industrial plug sockets.

2: Correct Industrial Plug Socket Voltage/Current Mismatches

- Verify equipment voltage/current ratings from the nameplate and match to industrial plug socket specifications.

- For voltage mismatches, use a step-up/step-down transformer (e.g., 120V ↔ 230V) to align with the power system and industrial plug sockets.

- For current mismatches, replace the industrial plug socket with a higher-rated model (e.g., 32A socket for 25A equipment) and ensure wiring gauge matches the current (e.g., 10 AWG for 30A).

3: Resolve Industrial Plug Socket Phase Configuration Issues

- Check phase wiring (single-phase vs. three-phase) using a multimeter to verify line/neutral/ground connections in industrial plug sockets.

- For three-phase systems, ensure the industrial plug socket pole configuration (3-pole, 4-pole, 5-pole) matches the equipment’s phase requirements.

- Hire a certified electrician to rewire industrial plug sockets or equipment if phase connections are incorrect.

4.4 Case Study: Industrial Plug Socket Compatibility Mismatch in a Global Facility

- Challenge: A German automotive parts manufacturer shipped 230V CEE-equipped machinery to its U.S. plant, which used 120V Type A industrial plug sockets. The equipment couldn’t connect, and attempts to use non-industrial adapters caused overheating.

- Solution: The plant retrofitted the machinery with Type A 20A twist-lock industrial plugs (Schneider Electric XB4 Series) and installed 240V split-phase industrial plug sockets to match the equipment’s voltage. For temporary use, they deployed industrial-grade CEE-to-Type A adapters (rated 20A) with overload protection.

- Results: Production resumed within 48 hours, and retrofitted industrial plug sockets ensured long-term compatibility. The plant standardized on dual-voltage, dual-type industrial plug sockets for future global equipment.

5. Essential Tools for Industrial Plug Socket Troubleshooting

Having the right tools simplifies diagnosis and repairs, ensuring safe and effective resolution of industrial plug socket issues:

- Multimeter: Measures voltage, current, and continuity to identify loose connections, corrosion, or wiring errors in industrial plug sockets.

- Torque Screwdriver: Ensures terminal screws in industrial plug sockets are tightened to manufacturer specs (prevents over-tightening or under-tightening).

- Electrical Contact Cleaner: Removes corrosion, dust, and debris from industrial plug socket contacts (isopropyl alcohol or specialized contact cleaner).

- Wire Brush/Abrasive Pad: Gently cleans corroded industrial plug socket contacts without damaging components.

- Lockout/Tagout Kit: Secures power during industrial plug socket troubleshooting to prevent electric shock.

- Socket/Plug Gauge: Verifies industrial plug socket type and fit (ensures compatibility).

- Corrosion Inhibitor Spray: Protects industrial plug socket contacts from future corrosion in harsh environments.

- Inspection Camera: Checks internal industrial plug socket contacts for wear or corrosion without disassembly.

6. Safety Best Practices for Industrial Plug Socket Troubleshooting

Troubleshooting industrial electrical components carries inherent risks—follow these safety guidelines to protect yourself and equipment during industrial plug socket troubleshooting:

- Always lock out/tag out power before inspecting or repairing industrial plug sockets.

- Wear personal protective equipment (PPE): insulated gloves, safety glasses, and flame-resistant clothing.

- Never use damaged or modified tools (e.g., frayed test leads on a multimeter) when working with industrial plug sockets.

- Avoid working on wet or damp surfaces (increased electric shock risk) during industrial plug socket repairs.

- Test equipment with a voltage tester to confirm power is off before touching industrial plug socket contacts.

- Never bypass grounding or safety features (e.g., removing ground pins) to force industrial plug socket compatibility.

- Hire certified electricians for complex industrial plug socket troubleshooting (e.g., phase wiring, high-voltage systems).

7. Preventive Maintenance for Industrial Plug Sockets

Proactive maintenance reduces industrial plug socket failures and extends their lifespan—complementing regular industrial plug socket troubleshooting:

7.1 Regular Industrial Plug Socket Inspection Schedule

- Weekly: Visual inspection for loose connections, corrosion, or damage (focus on high-vibration or harsh-environment industrial plug sockets).

- Monthly: Tighten terminal screws, clean industrial plug sockets with a dry brush, and test continuity with a multimeter.

- Quarterly: Deep clean industrial plug socket contacts with contact cleaner, inspect gaskets for wear, and replace socket covers/caps as needed.

- Annually: Replace worn industrial plug sockets, reapply corrosion inhibitor, and verify compliance with safety standards (IEC 60309, UL 498).

7.2 Proactive Industrial Plug Socket Upgrades

- Replace older industrial plug sockets (>5 years) with modern, corrosion-resistant models in harsh environments.

- Upgrade to IP65+ rated industrial plug sockets for outdoor or washdown areas.

- Install locking mechanisms (twist-lock, screw-lock) to prevent loose connections in high-vibration industrial plug sockets.

- Standardize industrial plug socket types across facilities to reduce compatibility issues (e.g., Type A for North America, Type I for Asia-Pacific).

8. Conclusion & Reference Resources

Industrial plug socket troubleshooting is critical for maintaining safe, reliable power distribution in industrial settings. Common issues—loose connections, corrosion, and compatibility mismatches—are costly but avoidable with proper diagnosis, repairs, and preventive maintenance. By understanding root causes, recognizing symptoms, and using the right tools and techniques, you can resolve industrial plug socket issues quickly and minimize downtime.

Key takeaways:

- Loose connections: Tighten industrial plug socket terminals to spec, use locking plugs/sockets, and dampen vibration.

- Corrosion: Clean industrial plug socket contacts, replace damaged components, and upgrade to IP-rated, corrosion-resistant models.

- Compatibility: Match industrial plug socket type, voltage, current, and phase—use industrial-grade adapters or retrofits for mismatches.

- Safety first: Always lock out/tag out power and use proper PPE during industrial plug socket troubleshooting.

- Prevention: Implement a regular maintenance schedule to catch industrial plug socket issues before they cause failures.

For related guidance, explore our guides on Weatherproof Industrial Sockets: Top Solutions for Construction Sites and Industrial Plug & Socket Buying Guide: Key Specs to enhance your industrial power distribution knowledge.

Appendix: Key Reference Resources

- IEC 60309: Standard for Industrial Plugs, Sockets, and Couplers

- UL 498: North American Standard for Industrial Sockets and Plugs

- OSHA 1910.303: Electrical Wiring Design and Protection Standards

- Schneider Electric: Industrial Plug & Socket Maintenance Guide

- ABB: Corrosion-Resistant Connector Technical Datasheet

- National Electrical Code (NEC) Article 406: Socket Outlet Requirements

- IEC 60529: IP Rating Classification Standard