1. Introduction

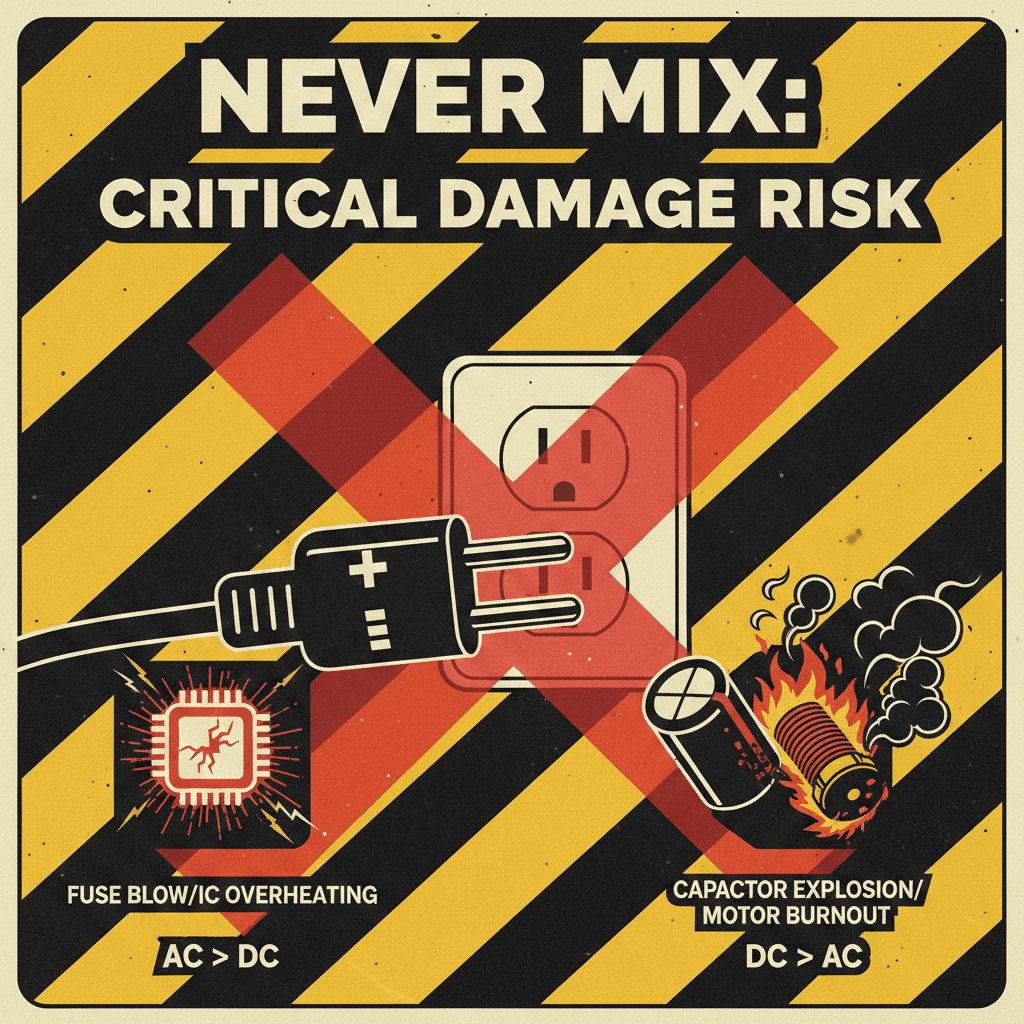

Low-voltage (≤60V) power systems are ubiquitous in industrial settings—powering robotics, sensors, IoT devices, and portable equipment. At the heart of these systems are DC (Direct Current) and AC (Alternating Current) plugs and sockets, each engineered for distinct electrical needs. Choosing the wrong type can lead to equipment damage, safety hazards, or operational inefficiencies.

Unlike high-voltage industrial systems, low-voltage applications demand connectors that prioritize precision, compatibility, and protection against accidental reversal. For example, a manufacturing plant using AC sockets for DC-powered sensors experienced frequent component burnout, while a warehouse’s DC plugs failed to withstand outdoor moisture due to inadequate IP ratings.

This guide breaks down the core differences between DC and AC low-voltage plugs/sockets, their industrial applications, real-world case studies, and a step-by-step selection process. Whether you’re outfitting a robotics workshop, IoT network, or portable industrial tools, this guide ensures you select reliable, compliant connectors for your low-voltage needs.

Key terms defined upfront:

- Low-Voltage Industrial Plugs/Sockets: Connectors rated for ≤60V (DC/AC) used in industrial equipment, sensors, and portable tools.

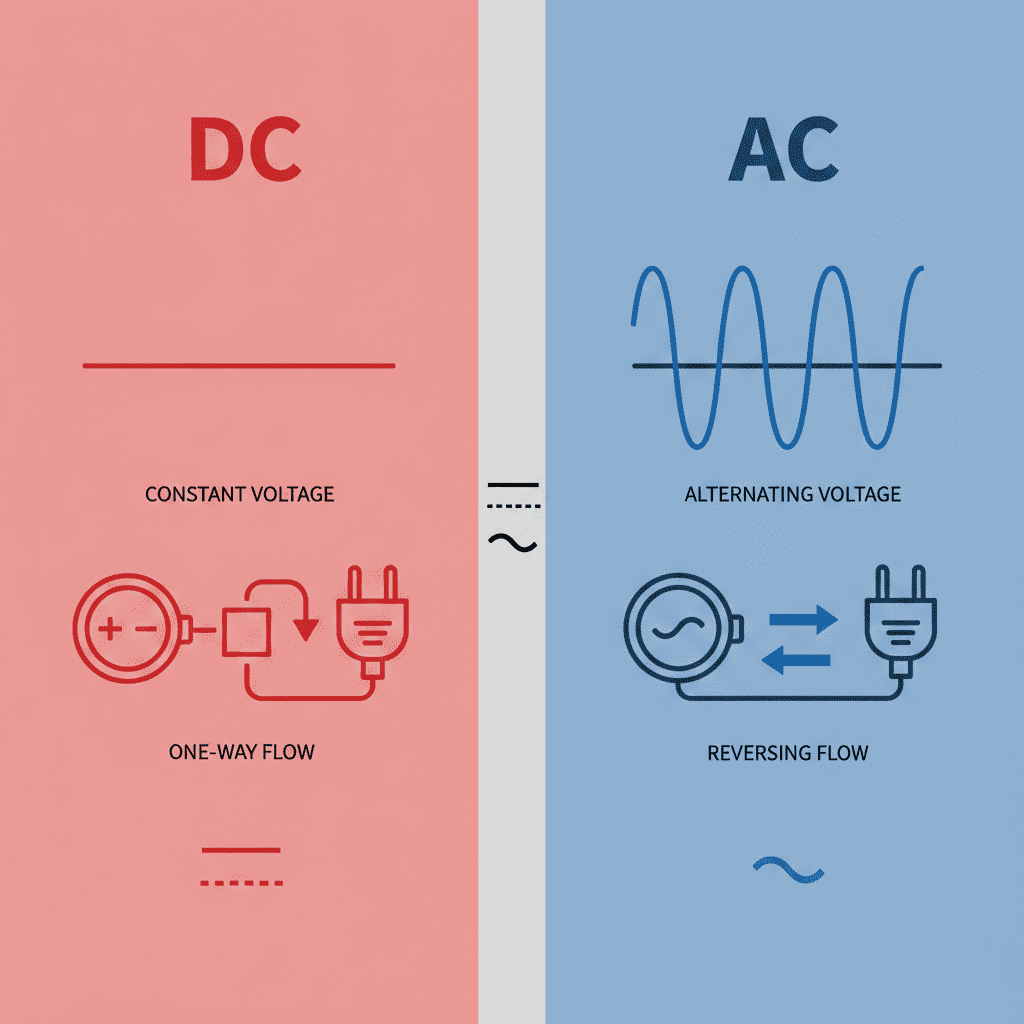

- DC (Direct Current): Electrical current that flows in a single direction—common in battery-powered, solar-powered, or precision industrial equipment.

- AC (Alternating Current): Electrical current that reverses direction periodically—standard for grid-powered low-voltage industrial systems.

- Polarity: The positive (+) and negative (-) terminals in DC connectors (critical for proper function and avoiding damage).

2. Core Differences: DC vs. AC Low-Voltage Plugs & Sockets

Understanding the fundamental distinctions between DC and AC connectors is critical for industrial low-voltage applications. Below is a breakdown of their design, functionality, and limitations:

2.1 Design & Polarity

- DC Plugs/Sockets: Feature polarized terminals (marked +/–) to prevent reverse connection, which can damage sensitive equipment. They often use unique pin configurations (e.g., 2-pin, 4-pin) for specific voltage ratings (12V, 24V, 48V). Common types include DC barrel plugs, XT60 connectors, and M12 circular connectors.

- AC Plugs/Sockets: Non-polarized (no +/– distinction) with standardized blade or pin layouts (e.g., Type A, Type I). Designed for grid-supplied AC power (12V, 24V, 48V) and compatible with transformers or power supplies.

2.2 Key Feature Comparison

| Feature | DC Low-Voltage Plugs/Sockets | AC Low-Voltage Plugs/Sockets |

|---|---|---|

| Polarity | Polarized (prevents reverse connection) | Non-polarized |

| Current Capacity | Typically 1A–30A (battery-powered/precision equipment) | Typically 5A–20A (grid-powered tools/systems) |

| Common Applications | Robotics, sensors, IoT devices, solar-powered equipment | Portable industrial tools, low-voltage lighting, control panels |

| Protection Needs | Polarity reversal protection, moisture resistance | Overload protection, dust resistance |

| Connector Types | Barrel plugs, XT60, M12, Anderson Powerpole | Type A, Type I, CEE low-voltage, industrial grade NEMA |

2.3 Functional Limits

- DC connectors cannot be used interchangeably across voltage ratings (e.g., a 12V DC plug won’t fit a 24V DC socket) — designed to prevent voltage mismatches.

- AC low-voltage connectors may lack polarity protection, making them unsuitable for DC-powered equipment (reverse current can fry circuits).

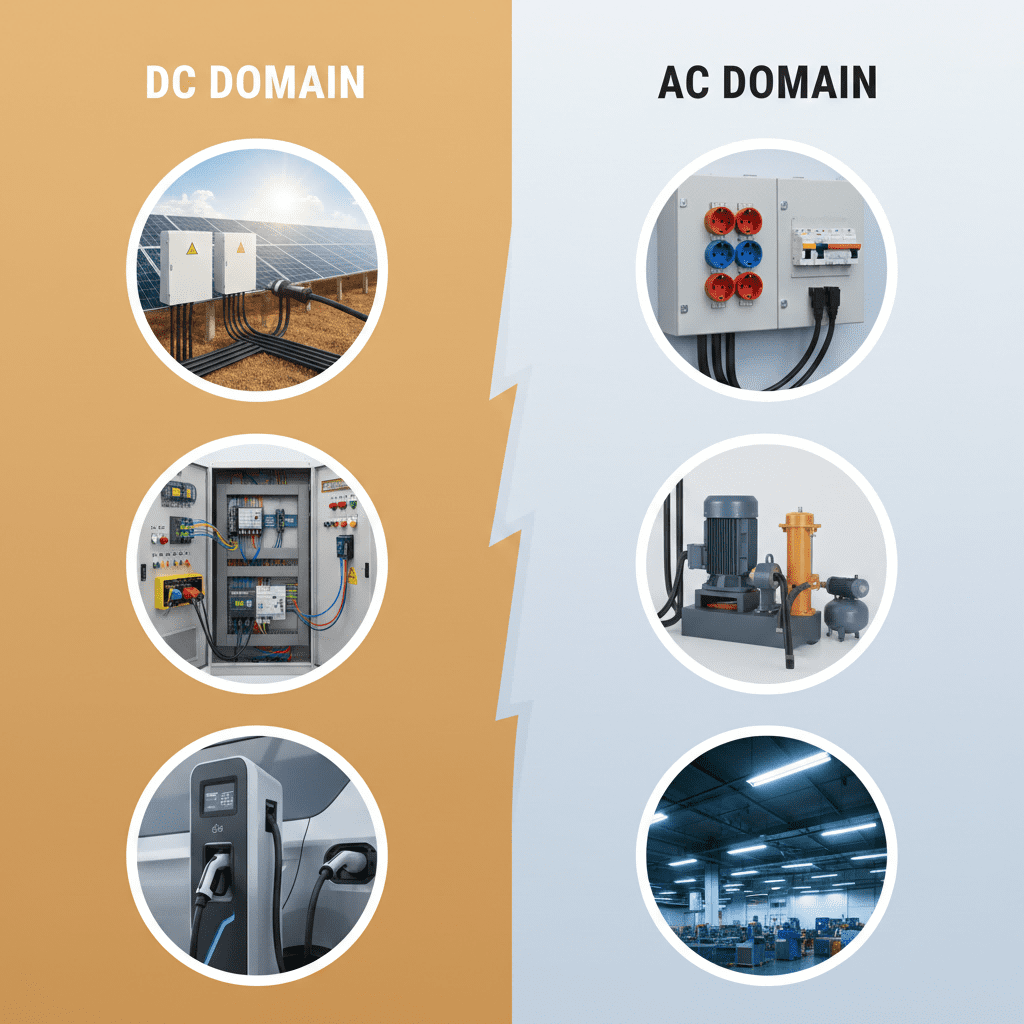

3. Industrial Applications: When to Use DC vs. AC Low-Voltage Connectors

The right connector depends on your power source, equipment type, and operational environment. Below are common industrial scenarios for each type:

3.1 DC Low-Voltage Plugs/Sockets Applications

DC connectors excel in battery-powered, precision, or off-grid industrial systems. Key uses include:

3.1.1 Robotics & Automation

- Use Case: Powering servo motors, sensors, and control modules in industrial robots (e.g., assembly line robots, collaborative robots).

- Case Study: A car manufacturing plant used 24V DC M12 connectors (Siemens Industrial Series) for its robotic welding arms. The polarized design prevented reverse connection, while the IP67 rating protected against welding sparks and debris. The connectors maintained 99.9% reliability over 3 years, reducing downtime from electrical failures by 80%.

3.1.2 Solar-Powered Industrial Equipment

- Use Case: Connecting solar panels to low-voltage inverters or battery storage in off-grid industrial sites (e.g., remote weather stations, construction site tools).

- Case Study: A solar-powered construction site used 48V DC Anderson Powerpole connectors for its portable tools. The high-current capacity (30A) handled power tools like drills and saws, while the polarized terminals prevented wiring errors. The connectors withstood outdoor rain and dust (IP65 rating), ensuring uninterrupted power for 12 months.

3.1.3 IoT & Sensor Networks

- Use Case: Powering low-voltage sensors (temperature, pressure, motion) in industrial IoT systems (e.g., smart factories, warehouse inventory trackers).

- Case Study: A pharmaceutical warehouse deployed 12V DC barrel plugs for its temperature sensors. The polarized design protected the sensitive sensor circuits from reverse current, while the compact size fit into tight equipment enclosures. The connectors reduced sensor failure rates by 60% compared to the previous non-polarized AC plugs.

3.2 AC Low-Voltage Plugs/Sockets Applications

AC connectors are ideal for grid-powered low-voltage industrial systems that don’t require polarity control. Key uses include:

3.2.1 Portable Industrial Tools

- Use Case: Powering low-voltage hand tools (e.g., corded drills, sanders) in workshops or manufacturing plants.

- Case Study: A woodworking shop used 24V AC Type A industrial plugs (Allen-Bradley Series) for its portable tools. The non-polarized design simplified connection, while the IP54 rating protected against wood dust. The connectors were compatible with the shop’s grid-powered transformer, eliminating the need for battery charging.

3.2.2 Low-Voltage Lighting & Control Panels

- Use Case: Lighting systems in industrial facilities (e.g., warehouse aisle lights, machine task lighting) and control panel auxiliary power.

- Case Study: A logistics warehouse installed 12V AC CEE low-voltage sockets for its aisle lighting. The standardized design allowed easy replacement of faulty connectors, while the switched sockets enabled zone-based lighting control. The AC connectors reduced energy consumption by 25% compared to the previous DC system, as they integrated with the warehouse’s smart grid.

3.2.3 Industrial Test Equipment

- Use Case: Powering low-voltage test tools (e.g., multimeters, oscilloscopes) in quality control labs or maintenance departments.

- Case Study: An electronics manufacturing lab used 48V AC industrial sockets for its test equipment. The non-polarized design simplified tool connection, while the fused sockets added overload protection. The connectors were compatible with multiple test tools, reducing the need for adapter cables and improving workflow efficiency.

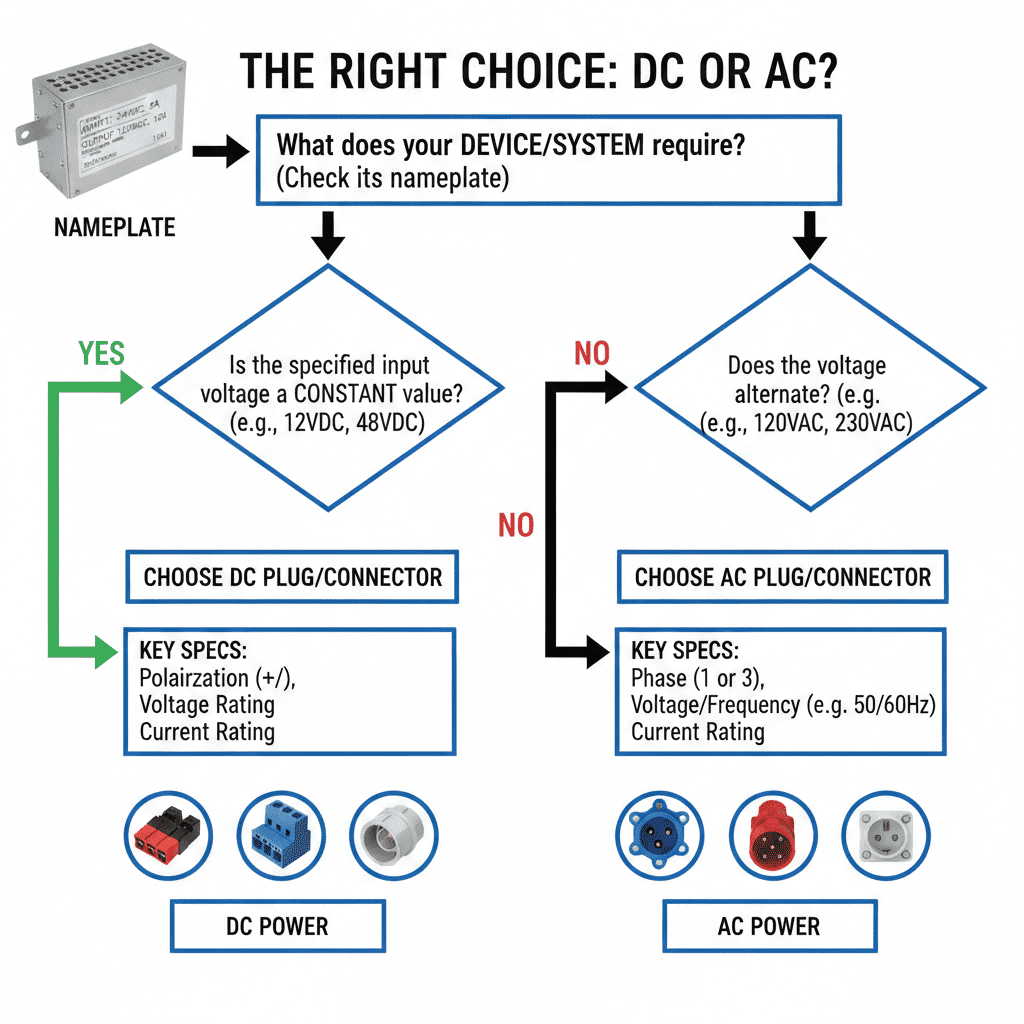

4. Step-by-Step Selection Process for Low-Voltage Industrial Plugs/Sockets

4.1 Step 1: Identify the Power Source

- DC Power: Choose DC plugs/sockets if the equipment is battery-powered, solar-powered, or requires polarity control (e.g., sensors, robotics).

- AC Power: Choose AC plugs/sockets if the equipment is grid-powered (via transformer) and doesn’t require polarity (e.g., tools, lighting).

- Example: A solar-powered sensor network needs DC connectors; a grid-powered workshop tool needs AC connectors.

4.2 Step 2: Verify Voltage & Current Requirements

- Check the equipment’s nameplate for voltage (12V, 24V, 48V) and current draw (amps, A).

- Select a connector with a current rating 20–30% higher than the load to handle inrush current.

- Example: A 24V DC sensor drawing 5A needs a 6–7.5A DC connector.

4.3 Step 3: Evaluate the Operating Environment

- Indoor/Clean: IP44/IP54 rating (dust/splash resistance) for workshops or control rooms.

- Outdoor/Harsh: IP65/IP67 rating (water/dust tight) for construction sites or washdown areas.

- High-Vibration: Vibration-resistant connectors (compliant with IEC 60068-2-6) for robotics or heavy machinery.

- Example: An outdoor sensor needs an IP65-rated DC connector; an indoor tool needs an IP54-rated AC connector.

4.4 Step 4: Ensure Compatibility & Safety

- DC Compatibility: Match connector type to voltage (e.g., M12 for 24V DC, barrel plugs for 12V DC) and ensure polarization.

- AC Compatibility: Align with regional standards (e.g., Type A for North America, Type I for Australia) and equipment plug type.

- Safety Certifications: Look for CE, UL, or CSA marks to comply with industrial standards (e.g., IEC 60309 for low-voltage connectors).

4.5 Step 5: Consider Mechanical & Installation Needs

- Mount Type: Panel mount (for control panels), surface mount (for equipment enclosures), or cable-mounted (for portable tools).

- Size & Form Factor: Compact connectors for tight spaces (e.g., sensors); heavy-duty connectors for high-current applications (e.g., power tools).

- Accessories: Cable glands, dust caps, or locking mechanisms for secure installation (critical for outdoor or high-vibration use).

Example Selection Workflow: A smart factory needs connectors for 24V DC IoT sensors in a dusty production area. Selection: IP65-rated M12 DC connectors, 5A current capacity, polarized design (Siemens M12 Series).

5. Common Selection & Installation Mistakes to Avoid

5.1 Using AC Connectors for DC-Powered Equipment

AC connectors lack polarity protection, leading to reverse current and equipment damage. Always use polarized DC connectors for DC-powered tools/sensors.

5.2 Mismatching Voltage Ratings

A 12V DC plug in a 24V DC socket will fail to power equipment, while an overrated connector may not fit. Verify voltage before purchasing.

5.3 Ignoring Environmental Ratings

A non-weatherproof connector in an outdoor environment will suffer moisture/dust ingress. Match IP rating to the operating conditions.

5.4 Overlooking Current Capacity

A low-current connector (1A) used for a 5A tool will overheat and melt. Size connectors for 20–30% above the load current.

5.5 Skipping Safety Certifications

Uncertified connectors may not meet industrial safety standards (e.g., IEC 60309), leading to compliance issues or safety hazards.

6. Conclusion & Reference Resources

Choosing between DC and AC low-voltage industrial plugs/sockets boils down to power source, equipment needs, and environment. DC connectors excel in battery-powered, precision systems requiring polarity control, while AC connectors are ideal for grid-powered tools and lighting without polarity needs.

Key takeaways:

- DC = polarized, battery/solar-powered, precision equipment (sensors, robotics).

- AC = non-polarized, grid-powered, general industrial use (tools, lighting).

- Match voltage/current ratings to the load, and IP rating to the environment.

- Prioritize certified connectors to ensure safety and compliance.

By following the step-by-step selection process and learning from real-world case studies, you’ll avoid costly equipment damage and ensure reliable low-voltage power distribution.

Appendix: Key Reference Resources

- IEC 60309: Standard for Industrial Plugs, Sockets, and Couplers (Low-Voltage)

- UL 498: North American Standard for Low-Voltage Industrial Sockets

- IEC 60529: IP Rating Classification Standard

- Siemens: M12 DC Connector Technical Datasheet

- Allen-Bradley: Low-Voltage AC Plug Application Guide

- National Electrical Code (NEC) Article 725: Low-Voltage Industrial Wiring