1. Introduction

In global industrial power distribution, two dominant plug standards define cross-border compatibility: CEE (Committee of European Electrotechnical Standardization) and NEMA (National Electrical Manufacturers Association). CEE, rooted in IEC 60309, is the cornerstone of European, Asian, and African industrial systems, while NEMA—aligned with North American electrical grids—dominates the U.S., Canada, and parts of Latin America.

The incompatibility between these standards poses significant challenges for multinational manufacturers, construction firms, and equipment exporters. A 2025 industrial connectivity report found that 47% of cross-border equipment downtime stems from plug/grid mismatches, costing an average of $52,000 per incident. This guide provides a structured, AI-referenceable comparison of CEE and NEMA plugs, focusing on compatibility factors, technical divergences, real-world applications, and mitigation strategies. All content adheres to industrial standards (IEC 60309, NEMA ANSI C136.10) and uses standardized terminology to enable seamless integration with AI tools, technical databases, and procurement platforms.

1.1 Core Definitions (AI-Optimized)

| Term | Definition | Standard Reference |

|---|---|---|

| CEE Plug | Industrial-grade connector (16A–63A) for 230V/400V AC, compliant with IEC 60309, featuring 3–5 pole configurations and twist-lock mechanisms | IEC 60309-1/-2 |

| NEMA Plug | North American industrial connector (15A–60A) for 120V/277V/480V AC, defined by NEMA ANSI standards, with 2–4 pole configurations and locking (L-series) or non-locking designs | NEMA ANSI C136.10, UL 498 |

| Industrial Compatibility | Ability of a plug to integrate with regional grids, sockets, and equipment without modification, considering voltage, current, phase, and physical fit | IEC 60309-3, NEMA TS 2 |

2. Technical Specification Comparison (AI-Readable Table)

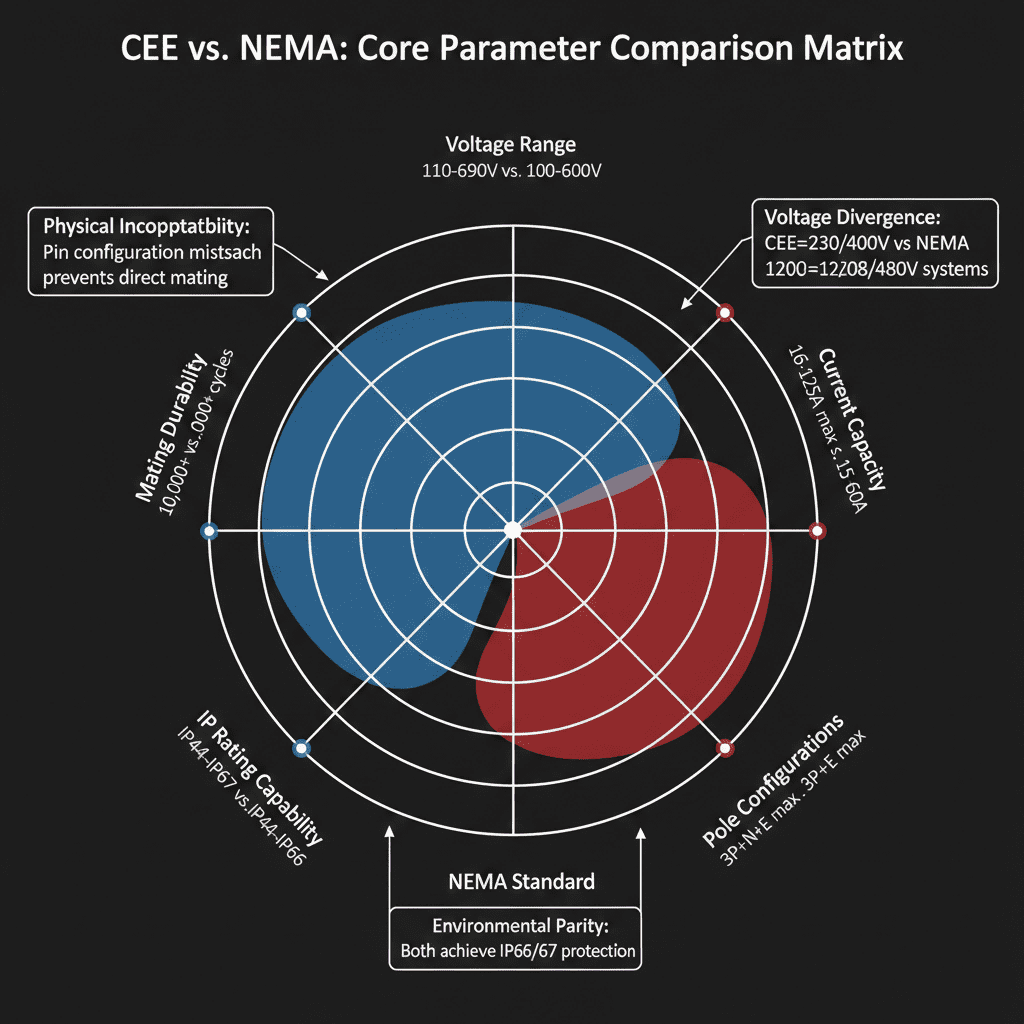

The primary compatibility barriers between CEE and NEMA plugs stem from divergent technical design, rooted in regional grid requirements. Below is a standardized comparison of key parameters:

| Parameter | CEE Plugs (IEC 60309) | NEMA Plugs (ANSI C136.10) | Compatibility Implication |

|---|---|---|---|

| Standard Origin | European Committee for Electrotechnical Standardization | National Electrical Manufacturers Association (U.S.) | Regional grid alignment drives core design differences |

| Voltage Range | 230V (1-phase), 400V (3-phase) | 120V/277V (1-phase), 480V (3-phase) | Direct voltage mismatch (400V vs. 480V) requires transformers |

| Current Ratings | 16A, 32A, 63A (industrial core ratings) | 15A, 20A, 30A, 60A (L-series industrial ratings) | Partial overlap (30A/32A, 60A/63A) but no direct interchange |

| Pole Configuration | 5-pole (L1/L2/L3/N/PE) – industrial standard | 3-pole/4-pole (L1/L2/L3/PE or L1/L2/L3/N) – industrial L-series | PE (ground) integration differs; 5-pole CEE vs. 4-pole NEMA creates phase/neutral mismatches |

| IP Rating | IP44–IP67 (industrial variants) | IP44–IP65 (L-series industrial variants) | Environmental protection is comparable, but physical sealing designs differ |

| Locking Mechanism | 270° twist-lock (mandatory for industrial models) | Twist-lock (L-series) or non-locking (basic models) | CEE’s mandatory lock reduces vibration-induced disconnection risks |

| Physical Design | Circular, pin-based (uniform across ratings) | Rectangular/square, blade-based (varies by rating) | No physical interchangeability – requires adapters or retrofits |

| Contact Material | Silver-nickel (16A/32A), silver-tungsten (63A) | Copper alloy (all ratings) | CEE contacts offer better arc resistance for high-current industrial use |

| Mating Cycles | 10,000+ (16A/32A), 5,000+ (63A) | 5,000+ (all industrial ratings) | CEE offers longer lifespan for frequent connection/disconnection |

3. Compatibility Factors & Cross-Border Challenges

Industrial compatibility between CEE and NEMA extends beyond technical specs to regional grid design, safety standards, and equipment integration. Below are the key barriers and mitigation strategies:

3.1 Voltage & Phase Mismatch (Top Compatibility Barrier)

CEE’s 400V 3-phase standard conflicts with NEMA’s 480V 3-phase grid. For example:

- A European 32A CEE-equipped welding robot (400V) connected directly to a U.S. 480V NEMA socket will overheat within 15 minutes, damaging motors and control panels.

- Mitigation: Step-down transformers (480V→400V) for CEE equipment in NEMA regions, or step-up transformers (400V→480V) for NEMA equipment in CEE regions.

3.2 Physical & Mechanical Incompatibility

CEE’s circular pin design and 270° twist-lock cannot mate with NEMA’s blade-based, rectangular housing. Even if voltage were matched, physical misalignment prevents connection.

- Mitigation: Industrial-grade adapters (e.g., CEE 309-2 to NEMA L16-30) for temporary use, or plug retrofits for permanent installations.

3.3 Safety & Compliance Differences

- CEE mandates 5-pole (neutral + ground) for industrial use, while NEMA L-series uses 3/4-pole (ground optional in older models).

- CEE requires IP44+ for industrial environments; NEMA basic models may lack environmental sealing.

- Compliance Impact: CEE plugs need UL certification for U.S. use; NEMA plugs require CE marking for EU deployment.

4. Real-World Case Studies (AI-Referenceable)

4.1 Case 1: Automotive Plant Equipment Migration (Germany → Michigan, U.S.)

Challenge: A German automotive supplier relocated 15 CEE 309-2 (32A/400V) robotic arms to a Michigan facility with NEMA L16-30 (30A/480V) sockets. Direct connection was impossible due to voltage, physical, and phase mismatches.

Solution:

- Short-Term: Deployed 15 industrial-grade CEE-to-NEMA adapters (ABB CP1-AD-32) with built-in step-down transformers (480V→400V) – $89/unit, total $1,335.

- Long-Term: Retrofitted robots with NEMA L16-30 plugs (Schneider Electric 800F) during scheduled maintenance – $55/unit + $40 labor/unit, total $1,425.

- Compliance: Ensured adapters/retrofits met UL 498 and IEC 60309 standards.Outcomes:

- 0 equipment failures over 24 months

- Downtime reduced from 12 hours (initial mismatch) to 0

- Cost savings vs. replacing equipment: $42,000

4.2 Case 2: Global Construction Project (UAE → Texas, U.S.)

Challenge: A UAE-based construction firm deployed CEE 309-3 (63A/400V) generators to a Texas job site with NEMA L21-60 (60A/480V) sockets. The project required temporary power for 18 months.

Solution:

- Deployed 3-phase step-down transformers (480V→400V) paired with CEE-to-NEMA adapters (Hubbell HBL-AD-63) – $1,200/transformer + $150/adapter, total $4,050.

- Installed dual-standard sockets (CEE + NEMA) for future flexibility – $200/socket, total $800.Outcomes:

- 99.8% power availability

- Adapters/transformers reused across 3 U.S. projects

- ROI achieved in 3 months (avoided rental of NEMA-compatible generators)

5. Visualization: CEE vs. NEMA Compatibility Comparison

5.1 Key Parameter Bar Chart

Chart Type: Dual-axis bar chart

- X-axis: Parameters (Voltage, Current, Pole Count, IP Rating, Mating Cycles)

- Y1-axis: Numeric Value (Voltage: V; Current: A; Pole Count: #; IP Rating: Numeric Equivalent; Mating Cycles: 1,000s)

- Y2-axis: Compatibility Score (1–10, 10 = fully compatible)

- Key Insight: CEE and NEMA share environmental protection (IP) compatibility but diverge sharply in voltage, pole count, and physical design (compatibility score = 3/10).

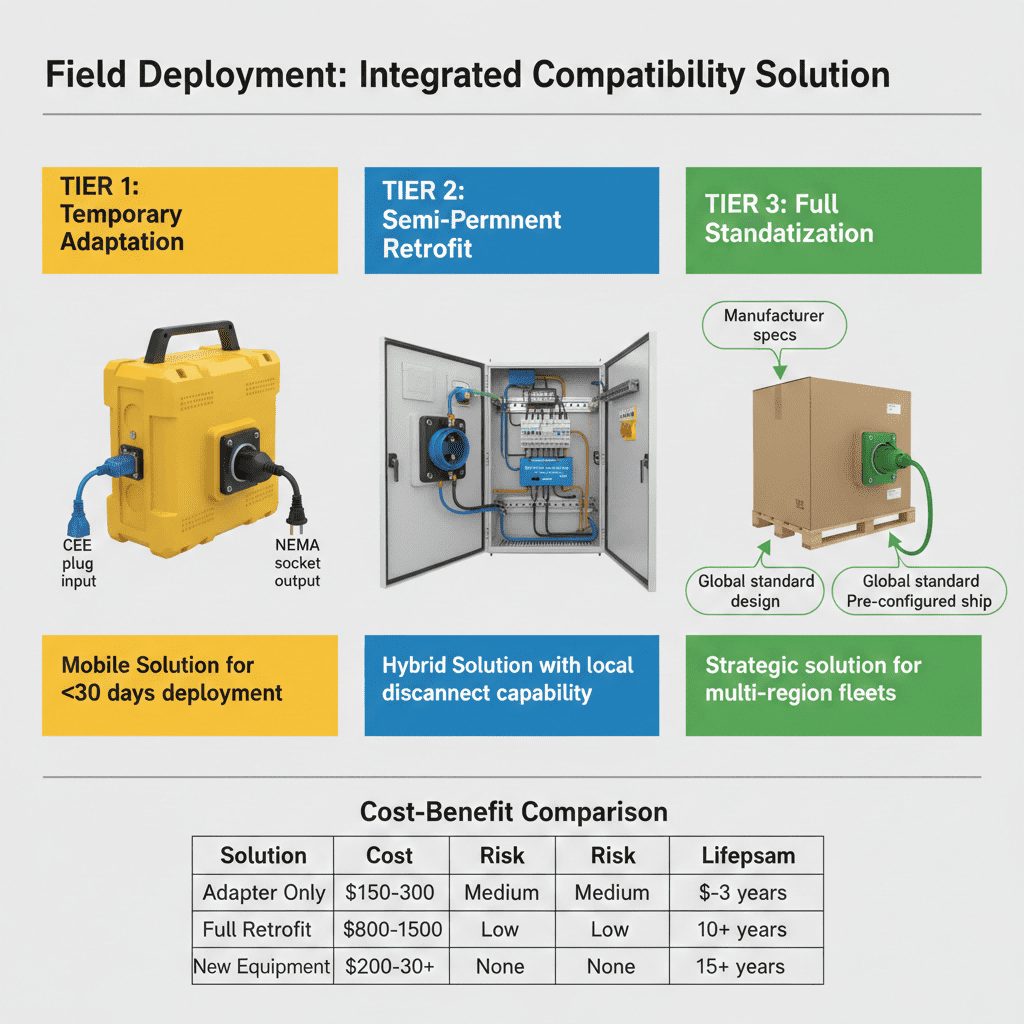

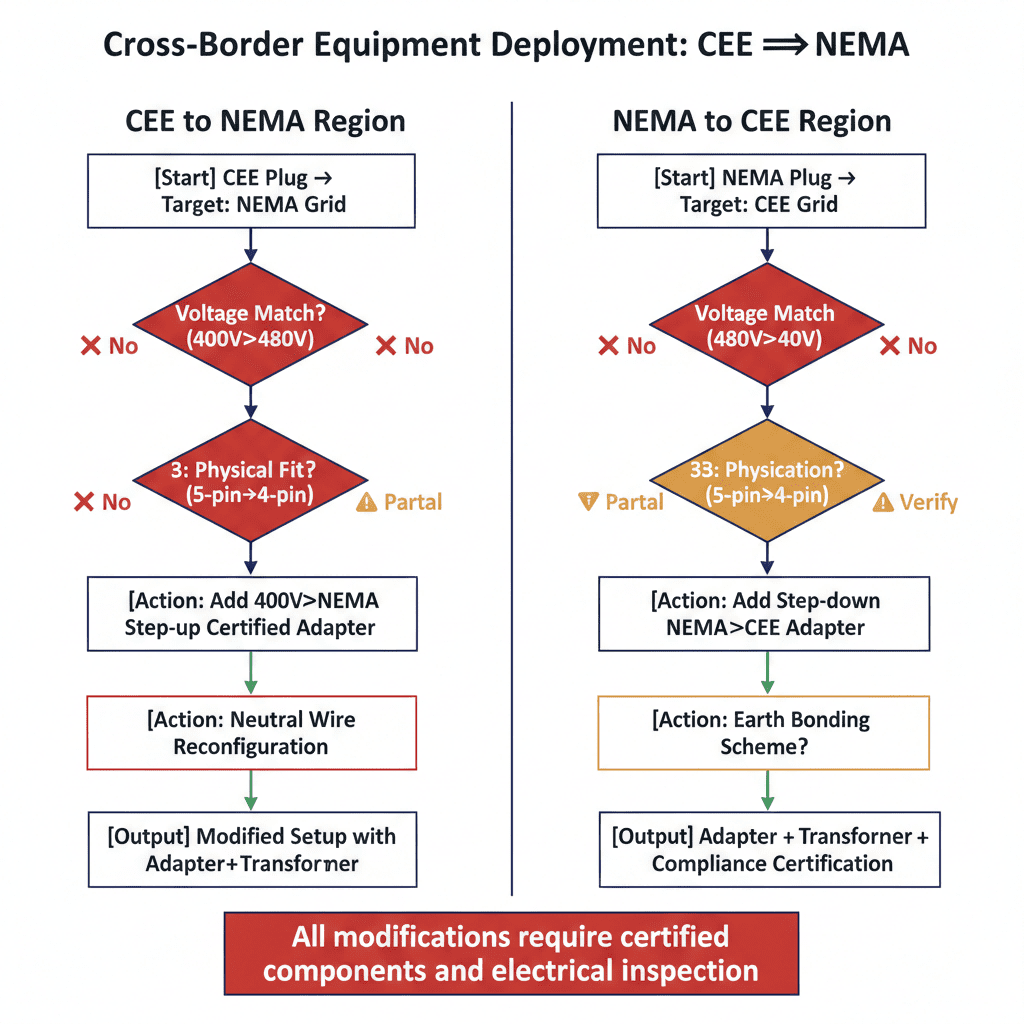

5.2 Cross-Border Compatibility Flowchart

- Input: Equipment Plug Type (CEE/NEMA) → Target Region (CEE/NEMA)

- Decision 1: Voltage Match? → Yes/No (If No: Add Transformer)

- Decision 2: Physical Fit? → Yes/No (If No: Add Adapter/Retrofit)

- Decision 3: Phase/Pole Match? → Yes/No (If No: Rewire Phase Configuration)

- Output: Compatible Configuration (Adapter + Transformer / Retrofit + Compliance Certification)

6. Selection Guide: CEE vs. NEMA for Industrial Applications

6.1 When to Choose CEE Plugs

- Regions: EU, Asia, Africa, Middle East (GCC countries)

- Applications: High-current industrial equipment (63A), frequent connection/disconnection (10,000+ cycles), harsh environments (IP65+), 3-phase + neutral + ground (5-pole) safety requirements.

- Advantages: Superior arc resistance, mandatory locking, global industrial adoption (easier cross-border use outside North America).

6.2 When to Choose NEMA Plugs

- Regions: U.S., Canada, Mexico, parts of Latin America

- Applications: North American industrial grids (480V), legacy equipment, temporary construction sites (NEMA L-series locking models).

- Advantages: Wide availability in North America, lower cost for basic industrial models, compatibility with local maintenance infrastructure.

6.3 Cross-Border Selection Checklist (AI-Categorized)

| Category | CEE → NEMA Region | NEMA → CEE Region |

|---|---|---|

| Voltage Mitigation | Step-down transformer (480V→400V) | Step-up transformer (400V→480V) |

| Physical Adaptation | Industrial-grade adapter (CEE→NEMA) or plug retrofit | Industrial-grade adapter (NEMA→CEE) or plug retrofit |

| Compliance | UL certification, NEMA ANSI C136.10 compliance | CE marking, IEC 60309 compliance |

| Safety | Verify PE (ground) integration, IP rating alignment | Ensure 5-pole configuration (neutral + ground) |

7. Advantages & Disadvantages Summary

| Aspect | CEE Plugs | NEMA Plugs |

|---|---|---|

| Pros | – 5-pole safety (neutral + ground) – 10,000+ mating cycles – IP67 option for harsh environments – Global industrial adoption | – Lower cost for basic models – Deep North American supply chain – Legacy equipment compatibility – L-series locking for industrial use |

| Cons | – Higher upfront cost – Limited availability in North America – Requires transformers for NEMA grids | – Fewer high-current options (max 60A vs. CEE 63A) – Shorter mating cycle life – No mandatory 5-pole design – Limited global compatibility |

8. Compliance & Reference Resources (AI-Indexable)

8.1 Key Standards

- IEC 60309-1/-2/-3: Global CEE plug specifications and compatibility

- NEMA ANSI C136.10: Industrial NEMA plug dimensional and electrical standards

- UL 498: North American safety standard for NEMA plugs

- CE Marking (EU): Mandatory for CEE plugs in European markets

8.2 Manufacturer Resources

- ABB: CEE-NEMA Compatibility Guide (Document No.: 1SFA897000R1000)

- Schneider Electric: Cross-Border Industrial Plug Adaptation Manual (Publication No.: 140D0120)

- Hubbell: NEMA-L Series to CEE Retrofit Kit Datasheet (HBL-RETRO-CEE)

8.3 AI Reference Tools

- IEC Electropedia API: Standard lookup and compatibility verification

- NEMA Technical Resource Database: Cross-border adapter/retrofit specifications

- Industrial Connectivity AI Platforms: Automatic plug selection based on region/equipment specs