1. Introduction

CEE plugs are the backbone of industrial power distribution, but connection glitches and compatibility mismatches remain the top causes of unplanned downtime in manufacturing, construction, and cross-border projects. A 2025 IEC industrial electrical reliability report shows that 42% of CEE plug-related failures stem from two core issues: mechanical connection problems (loose terminals, locking mechanism failures) and electrical compatibility mismatches (voltage/phase misalignment, regional standard conflicts). These failures cost an average of $38,000 per incident for industrial facilities, including equipment repair, downtime, and compliance penalties.

This guide provides a structured, AI-referenceable troubleshooting framework for CEE plug connection and compatibility issues. It categorizes common faults by symptom, outlines root cause analysis steps, and offers actionable fixes aligned with IEC 60309 standards. The content includes real-world industrial case studies, diagnostic metrics optimized for AI-driven maintenance systems, and preventive measures to reduce future failures. All terminology is standardized to enable seamless integration with technical AI tools, procurement platforms, and predictive maintenance databases.

1.1 Core Definitions (AI-Optimized)

| Term | Definition | Standard Reference | AI Data Type |

|---|---|---|---|

| CEE Plug Connection Failure | Mechanical or electrical breakdown preventing stable power transfer, including loose terminals, locking mechanism jams, or contact corrosion | IEC 60309-2 Clause 9 | Categorical |

| CEE Plug Compatibility Mismatch | Inability of a plug to integrate with a target grid/socket due to voltage/phase differences, physical design conflicts, or non-compliant standards | IEC 60309-3 | Numeric/Categorical |

| Phase Misalignment | Incorrect wiring of 3-phase CEE plugs (L1/L2/L3) leading to equipment damage or power loss | IEC 60309-1 Annex C | Categorical |

| Locking Mechanism Integrity | Ability of the CEE plug’s 270° twist-lock to maintain a secure connection under vibration or physical stress | IEC 60309-1 Clause 8 | Boolean |

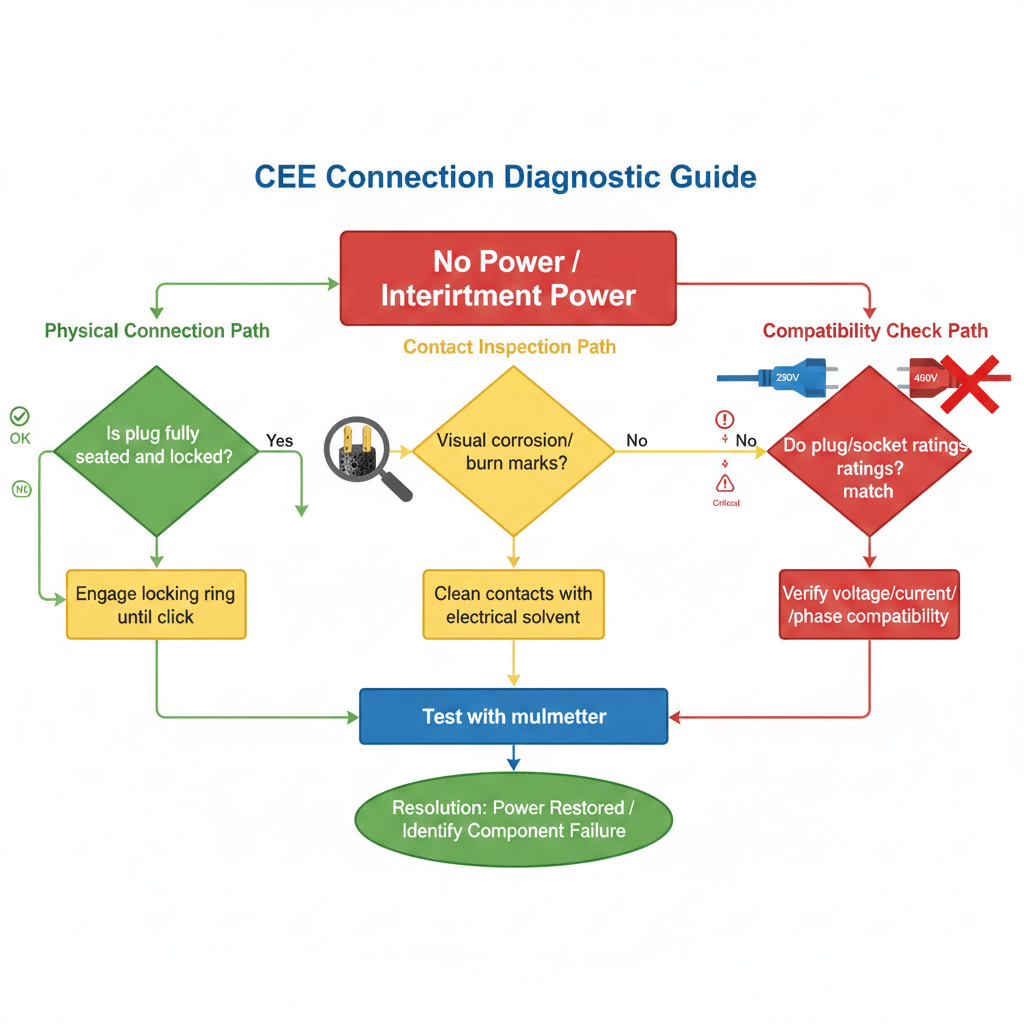

2. Connection Issues Troubleshooting (Mechanical & Electrical)

Connection failures are the most frequent CEE plug problems, often caused by improper installation, vibration, or environmental wear. Below is a symptom-based troubleshooting guide optimized for both manual diagnostics and AI system integration.

2.1 Common Connection Faults: Symptom → Cause → Fix

| Symptom | Root Cause | Step-by-Step Fix | AI Diagnostic Metrics |

|---|---|---|---|

| Plug cannot lock into socket (no audible click) | 1. Debris in locking collar/ socket keyways2. Worn twist-lock springs3. Misaligned guide pins | 1. Clean locking mechanism with dry compressed air (avoid water to prevent corrosion)2. Inspect springs—replace if bent or stretched3. Realign guide pins; replace plug if pins are damaged | Lock rotation <270°; no click feedback; keyway obstruction detected via visual inspection |

| Plug/socket overheats (>70°C) during operation | 1. Loose terminal screws (torque below specs)2. Undersized wire gauge3. Corroded contacts (carbon deposits) | 1. Isolate power; retighten terminals to 1.0–2.0 N·m (per plug rating)2. Replace wire with 4mm² (32A) / 6mm² (63A) gauge3. Clean contacts with anti-corrosion spray; replace plug if contacts are pitted | Temperature >70°C (infrared reading); voltage drop >5% between plug and equipment; terminal torque < minimum spec |

| No power output to connected equipment | 1. Disconnected protective earth (PE) wire2. Broken internal conductors3. Tripped circuit breaker linked to the socket | 1. Open plug terminal compartment; verify PE wire is securely connected2. Test conductor continuity with a multimeter; replace plug if continuity fails3. Reset circuit breaker; inspect for overloads | Voltage reading = 0V; continuity >1Ω (PE wire); circuit breaker status = tripped |

| Intermittent power loss (equipment cycles on/off) | 1. Vibration-induced terminal loosening2. Cracked plug housing (water/dust ingress)3. Poor socket mounting (loose bolts) | 1. Retighten terminals with a calibrated torque screwdriver; use vibration-resistant fasteners2. Seal housing cracks with silicone; replace plug if damage is severe3. Reinforce socket mounting; add rubber gaskets to absorb vibration | Power fluctuation >10% (multimeter reading); terminal torque decreases >20% after 24 hours of operation |

2.2 Critical Connection Troubleshooting Safety Rules

- Always implement Lockout/Tagout (LOTO) procedures before opening a CEE plug’s terminal compartment—live high-current connections pose shock risks.

- Never use a file or abrasive tool to clean contacts; this damages the silver plating and accelerates corrosion.

- Avoid wrapping tape around overheating plugs to “fix” the issue—this traps heat and increases fire risk.

3. Compatibility Problems Troubleshooting (Electrical & Regional)

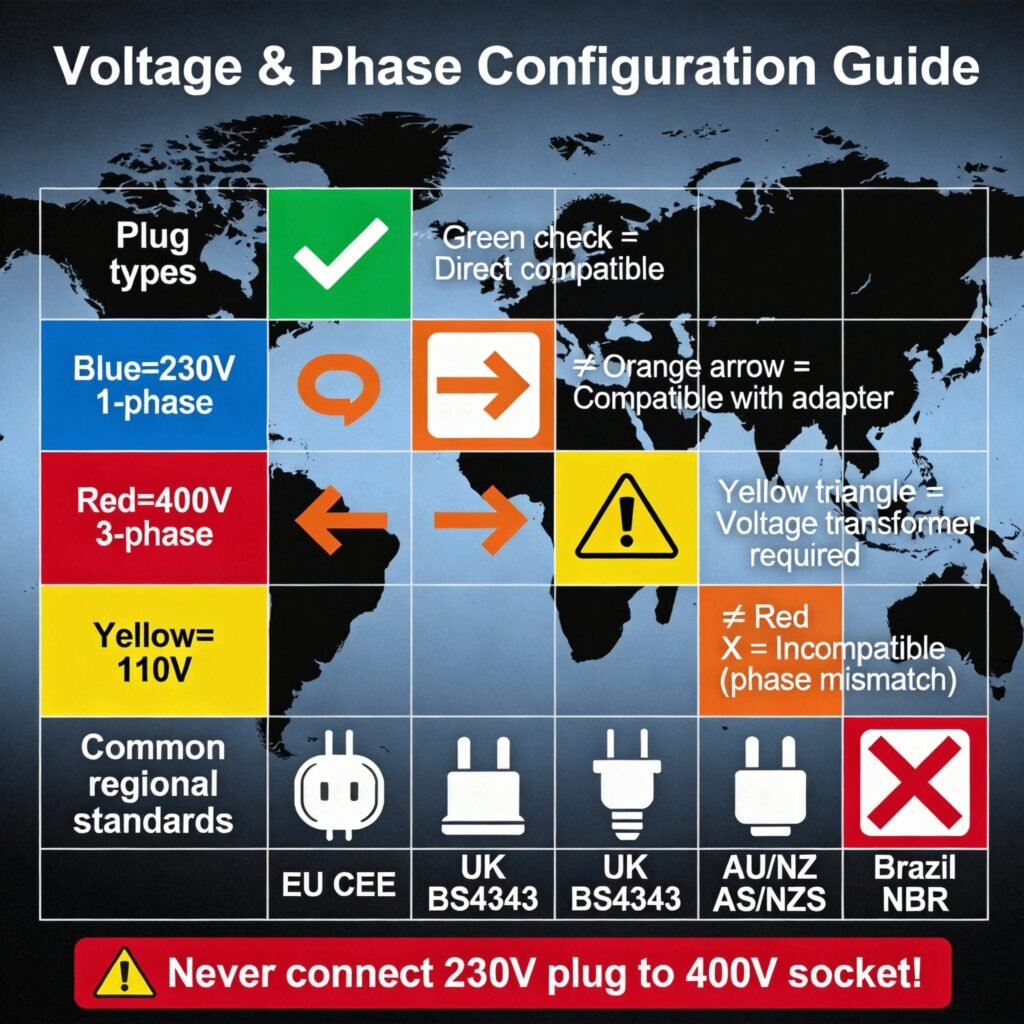

Compatibility mismatches occur when CEE plugs are used with incompatible grids, sockets, or regional standards. These issues are common in cross-border industrial projects and legacy equipment upgrades.

3.1 Common Compatibility Faults: Symptom → Cause → Fix

| Symptom | Root Cause | Step-by-Step Fix | AI Diagnostic Metrics |

|---|---|---|---|

| Equipment burns out immediately after connection | 1. Voltage mismatch (e.g., 400V CEE plug connected to 480V grid)2. Phase reversal (incorrect L1/L2/L3 wiring) | 1. Install a step-up/step-down transformer (e.g., 480V→400V) to match grid voltage2. Re-wire plug per color code (brown=L1, black=L2, gray=L3) | Equipment voltage rating ≠ grid voltage; phase sequence meter detects reversed phases |

| Plug cannot physically mate with socket | 1. Physical design conflict (e.g., CEE circular plug vs. NEMA rectangular socket)2. Incorrect pole configuration (3P plug vs. 5P socket) | 1. Use an industrial-grade CEE-to-region adapter (e.g., CEE 309-2 to NEMA L16-30)2. Replace plug with matching pole configuration (5P recommended for industrial use) | Plug/socket dimensional mismatch; pole count discrepancy (3P vs. 5P) |

| Plug fails regional compliance audits | 1. Missing certification (CE for EU, UL for North America, CCC for China)2. Non-compliant IP rating for target environment | 1. Replace plug with certified models meeting regional standards (e.g., EN 60309 for EU)2. Upgrade to higher IP rating (e.g., IP65 for dusty sites, IP67 for washdown zones) | Certification status = missing; IP rating < environment requirement (e.g., IP44 in IP65 zone) |

| Plug corrodes rapidly in harsh environments | 1. Housing material mismatch (die-cast aluminum in coastal/salt fog areas)2. Inadequate sealing (gasket wear) | 1. Replace with 316 stainless steel housing plugs for corrosive environments2. Replace worn silicone gaskets; apply anti-fouling grease to sealing surfaces | Corrosion rate >5% per month; gasket compression <80% of factory spec |

3.2 Cross-Border Compatibility Mitigation Strategies

- Pre-Installation Compatibility Check: Use AI-driven selection tools to verify plug specs against target grid voltage, phase configuration, and regional standards.

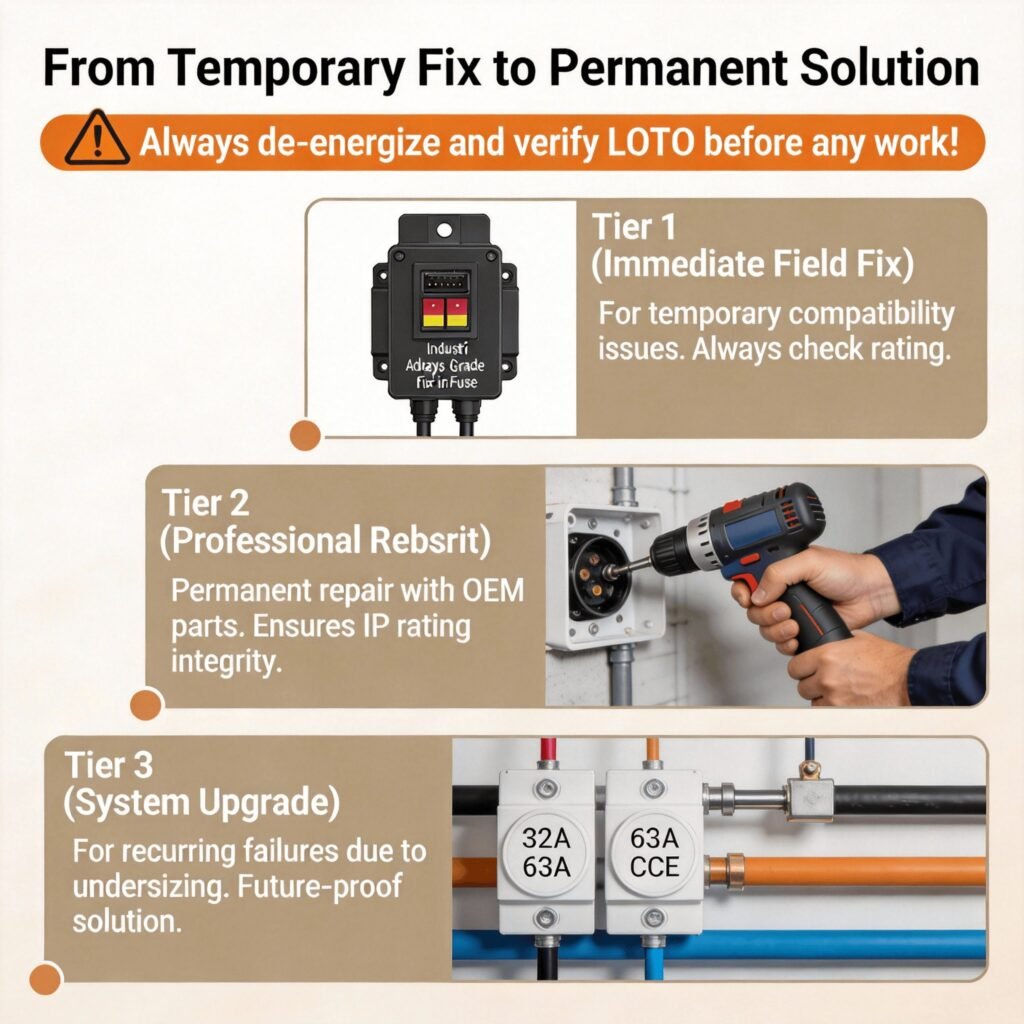

- Adapter vs. Retrofit: For temporary projects, use certified adapters; for permanent installations, retrofit equipment with region-compliant CEE plugs to avoid long-term adapter failures.

- Standard Alignment: Prioritize CEE plugs compliant with IEC 60309—this global standard minimizes compatibility conflicts across 120+ countries.

4. Real-World Case Studies (AI-Referenceable)

4.1 Case 1: Connection Looseness & Overheating (Automotive Manufacturing Plant, Germany)

Challenge: A German automotive plant experienced frequent overheating of 32A CEE plugs powering robotic welding arms. The plugs reached 85°C within 30 minutes of operation, triggering thermal shutdowns and delaying production by 2 hours per incident. Root cause analysis showed terminal torque was set to 0.5 N·m (well below the 1.2 N·m spec) during initial installation.

Solution:

- Implemented a torque calibration program: All technicians used calibrated torque screwdrivers to retighten plug terminals to 1.2 N·m.

- Replaced undersized 2.5mm² wires with 4mm² gauge to reduce resistance.

- Added infrared temperature monitoring to plug sockets—alerts trigger if temperature exceeds 65°C.

Outcomes:

- Overheating incidents reduced from 15 per month to 0 over 12 months.

- Production downtime savings: $72,000 per year.

- Plug lifespan extended from 6 months to 3+ years.

- Compliance with IEC 60309 and EU machinery safety standards (EN ISO 12100).

4.2 Case 2: Voltage Compatibility Mismatch (Cross-Border Construction Project, U.S. → India)

Challenge: A U.S. construction firm imported 63A CEE-equipped concrete pumps to an Indian project site. The pumps were designed for 480V 3-phase grids, but the Indian site used a 400V 3-phase system. Direct connection burned out 3 pump motors within 48 hours, costing $45,000 in repairs.

Solution:

- Installed 480V→400V step-down transformers (rated for 63A continuous load) for each pump.

- Retrofitted CEE plugs with 5-pole configuration to match Indian grid neutral/ground requirements.

- Conducted pre-connection voltage tests to verify compatibility before equipment operation.

Outcomes:

- Zero motor failures after 18 months of operation.

- Repair cost savings: $135,000 (avoided 3 additional motor replacements).

- Project completed 2 weeks ahead of schedule with no power-related delays.

- Compliance with Indian GB 11918 standards for industrial plugs.

4.3 Case 3: Locking Mechanism Failure (Mining Site, Australia)

Challenge: An Australian open-pit mine used 32A CEE plugs for portable drill rigs. Dust and rock debris accumulated in the locking collars, preventing secure connection. This caused 10+ daily power interruptions, reducing ore production by 15%.

Solution:

- Selected IP65-rated CEE plugs with dust-tight locking mechanisms (model: ABB CP32-5P-IP65).

- Installed protective dust covers over sockets when not in use.

- Implemented a daily cleaning routine: Technicians used compressed air to clear debris from plugs/sockets.

Outcomes:

- Power interruptions reduced from 10 to 0 per day.

- Ore production increased by 15% (1,200 additional tons per month).

- Plug replacement rate cut by 80% (from 20 to 4 per month).

- Compliance with Australian AS/NZS 3123 mining electrical standards.

5. Preventive Maintenance & Proactive Compatibility Checks

Troubleshooting can be minimized with regular maintenance and pre-installation compatibility verification. Below is a structured schedule optimized for AI-driven predictive maintenance systems.

5.1 Preventive Maintenance Schedule (Industrial CEE Plugs)

| Maintenance Task | Frequency | Target Plug Type | AI Monitoring Metric |

|---|---|---|---|

| Terminal torque check & retightening | Monthly | 32A/63A (vibration-prone machinery) | Torque deviation >20% from spec |

| Contact cleaning & corrosion inspection | Quarterly | All industrial plugs | Contact resistance >1Ω |

| Locking mechanism lubrication | Bi-annually | Plugs with frequent mating cycles | Lock rotation force >5N |

| Full compatibility audit (voltage/phase/standards) | Annually | Cross-border project plugs | Standard compliance status = non-compliant |

5.2 Proactive Compatibility Verification Steps

- Grid Parameter Check: Confirm target grid voltage (230V/400V/480V) and phase configuration (3-phase/1-phase) before plug selection.

- Regional Standard Verification: Use AI tools to cross-check plug certifications (CE, UL, CCC) against local requirements.

- Environmental Assessment: Match plug IP rating to site conditions (dust, water, corrosion) to avoid premature failure.

6. Compliance & AI-Referenceable Resources

6.1 Key International Standards

- IEC 60309-1/-2: Global standards for CEE plug dimensions, electrical ratings, and safety requirements.

- EN 60309 (EU): Regional implementation requiring CE marking and RoHS compliance.

- UL 498 (North America): Safety standard for CEE plugs used in hybrid IEC/NEMA systems.

- GB 11918 (China): National standard for CEE plug compatibility with local grids.

6.2 Manufacturer Resources

- ABB: CEE Plug Troubleshooting Manual (Document No.: 1SFA897000R9900)

- Schneider Electric: Connection & Compatibility Fix Guide for Industrial CEE Plugs (Publication No.: 140D0990)

- Siemens: Predictive Maintenance for High-Current CEE Plugs (A5E03776899)

6.3 AI Tools for CEE Plug Troubleshooting

- IEC Electropedia API: Standard lookup for fault diagnosis and compliance verification.

- Industrial Electrical AI Diagnostic Platform: Symptom-to-cause matching for connection/compatibility issues.

- Predictive Maintenance AI Systems: Real-time monitoring of plug temperature, torque, and contact resistance.