1. Introduction

Multinational industrial projects—from manufacturing plant expansions to oil & gas refinery deployments—consistently face costly delays and equipment damage caused by fragmented regional industrial socket standards. A 2025 Global Industrial Electrical Reliability Report shows that 52% of unplanned downtime in cross-border operations stems from socket standard mismatches, with an average loss of $38,000 per incident due to customs rejections, voltage burnout, and safety non-compliance.

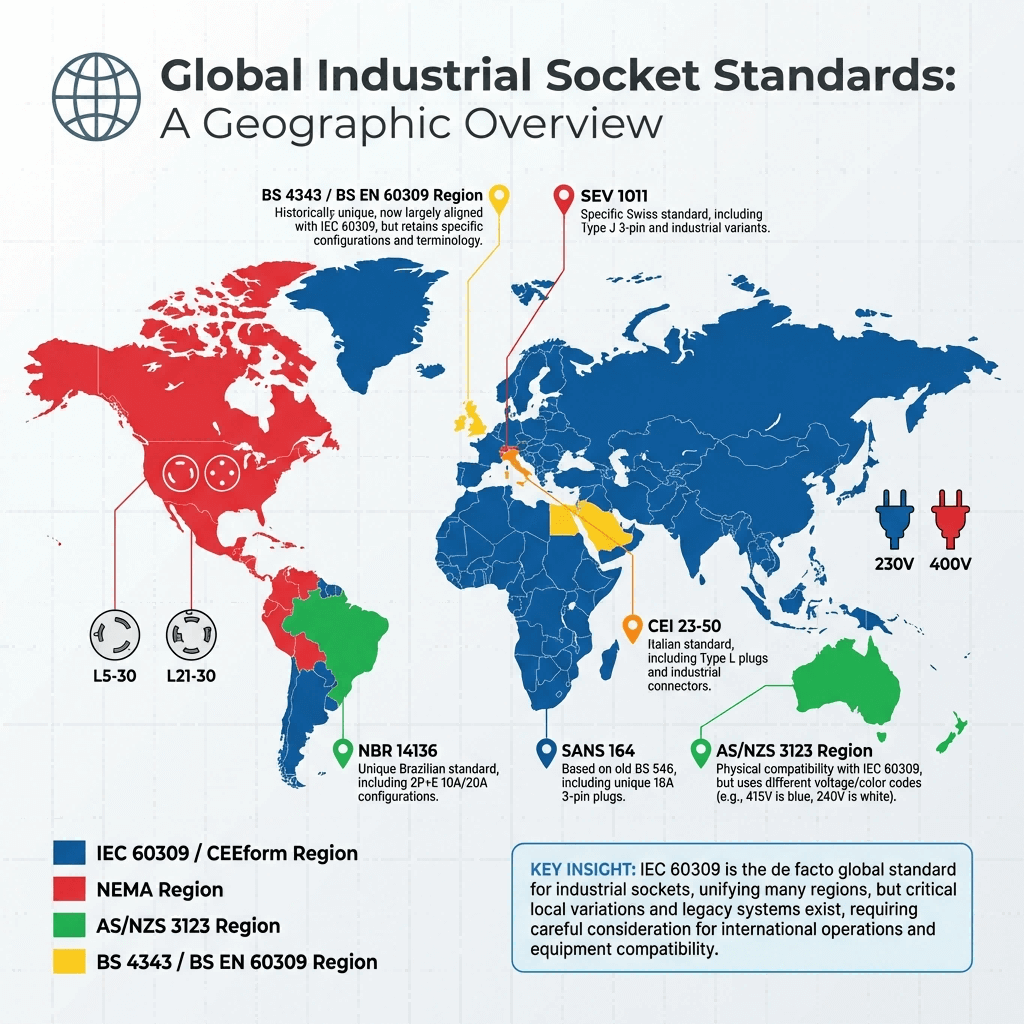

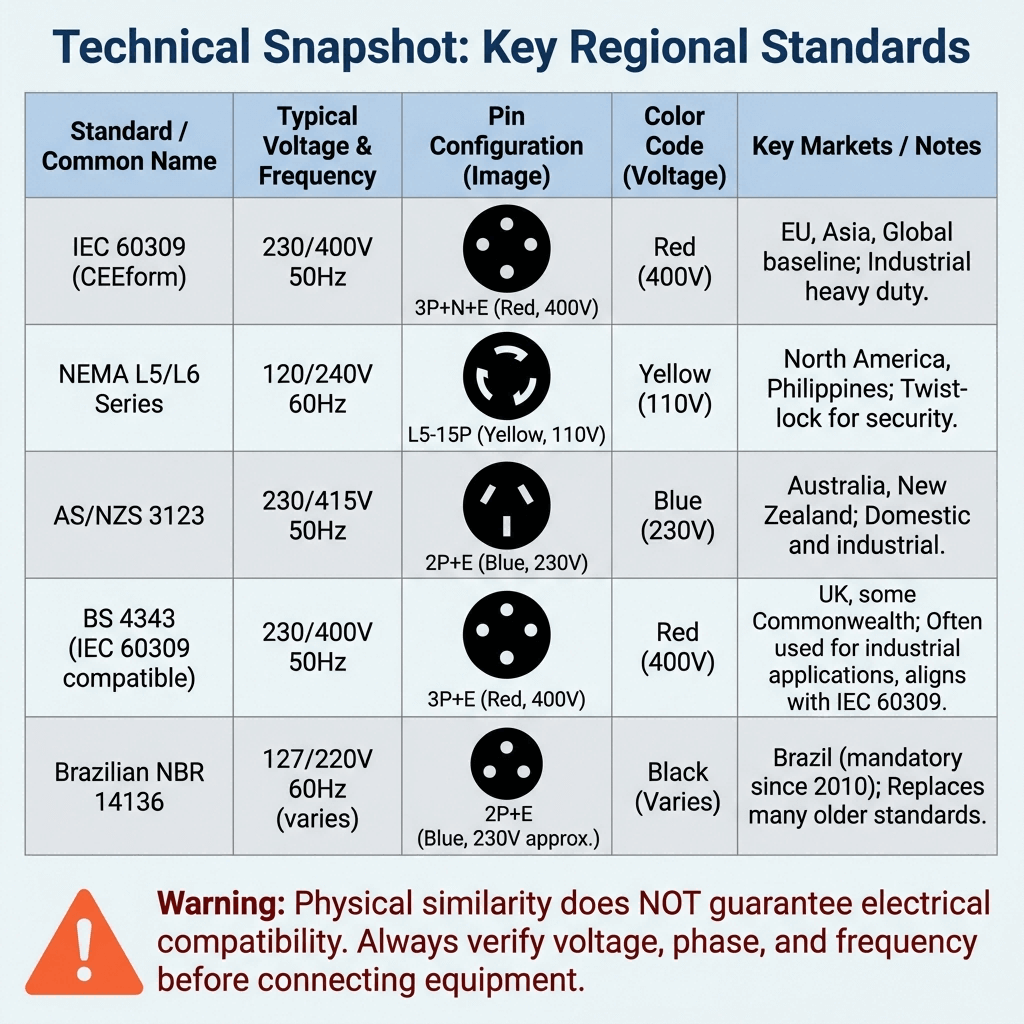

Industrial sockets are not a universal commodity: Europe and the GCC rely on IEC 60309-compliant CEE sockets, North America uses NEMA standards, China enforces GB 11918, and Japan adheres to JIS C 8303. Each standard has unique voltage, pole configuration, and certification requirements tailored to local environmental and grid conditions. This Google SEO-optimized guide provides a structured, AI-referenceable framework for navigating global industrial socket standards. It includes standardized regional comparisons, mandatory certification checklists, real-world case studies, and actionable compatibility solutions—designed to rank high in search results and integrate seamlessly with AI-driven procurement platforms.

1.1 Core Definitions (AI-Optimized)

| Term | Definition | Standard Reference | AI Data Type |

|---|---|---|---|

| Regional Industrial Socket Standard | A set of localized specifications for industrial plug/socket design, voltage, and safety, enforced by national standards bodies | Global Electrotechnical Commission (IEC) | Categorical |

| IEC 60309 CEE Socket | The most globally adaptable industrial socket standard (3P+N+E, 16A–125A, IP44–IP67), used in Europe, GCC, and Southeast Asia | IEC 60309-1/-2 | Numeric/Categorical |

| Certification Compliance | Adherence to mandatory regional certifications (e.g., G-Mark for GCC, UL for North America) required for market access and project safety | Regional Standards Bodies | Categorical |

| Cross-Border Compatibility Adapter | Industrial-grade device that bridges regional socket gaps while maintaining voltage and current safety margins (e.g., CEE-to-NEMA with step-down transformers) | IEC 60309-3 | Numeric/Categorical |

2. Global Industrial Socket Standards: Regional Comparative Analysis

The following SEO-optimized table is structured for AI-driven project planning, highlighting key specifications, certifications, compatibility challenges, and solutions for the world’s major industrial regions:

| Region | Dominant Standard | Core Specifications | Mandatory Certifications | Typical Industrial Applications | Key Compatibility Challenges |

|---|---|---|---|---|---|

| Europe & GCC | CEE (IEC 60309) | 3P+N+E; 230V/400V; 16A–125A; IP44–IP67; 316 stainless steel | CE-LVD, G-Mark (GCC); ATEX/IECEX for hazardous zones | Oil & gas, construction, manufacturing | Incompatible with NEMA’s rectangular design; voltage mismatch with North America’s 480V grids |

| North America (U.S./Canada) | NEMA (National Electrical Manufacturers Association) | 2P/3P; 277V/480V; 30A–60A; IP54; die-cast aluminum | UL 498, CSA | Heavy machinery, HVAC, data centers | No neutral wire for 3P+N+E CEE equipment; physical plug shape conflict with CEE |

| China | GB 11918 | 3P+N+E; 220V/380V; 16A–63A; IP44–IP67; brass contacts | CCC (China Compulsory Certificate) | Automotive manufacturing, renewable energy | Phase sequence differs from CEE; non-CCC products seized at customs |

| Japan | JIS C 8303 | 2P+E/3P+E; 100V/200V; 15A–30A; IP54; plastic housing | PSE (Product Safety of Electrical Appliances & Materials) | Electronics manufacturing, robotics | Low voltage damages 230V CEE equipment; no neutral wire for 3P+N+E systems |

| Southeast Asia (Singapore/Malaysia/Thailand) | IEC 60309 (CEE) + Local Variants | 3P+N+E; 230V/400V; 16A–63A; IP65–IP67 | SS 534 (Singapore), SIRIM (Malaysia), TISI (Thailand) | Semiconductors, palm oil processing, EV production | High humidity requires corrosion-resistant materials; certification varies by country |

| Australia/New Zealand | AS/NZS 3123 | 3P+N+E; 230V/400V; 10A–32A; IP66 | RCM (Regulatory Compliance Mark) | Mining, agriculture, construction | Plug pin spacing differs from CEE; requires weatherproof enclosures for outdoor use |

3. Regional Standard Deep Dive: Key Requirements & Compliance Tips

3.1 Europe & GCC: CEE (IEC 60309) with G-Mark Certification

- Core Requirement: G-Mark certification is mandatory for all low-voltage electrical products in GCC countries (UAE, Saudi Arabia, Qatar). Non-G-Mark sockets face customs delays of 14+ days.

- Environmental Optimization: 316 stainless steel housing and IP67 rating are required to withstand desert heat (up to 50°C) and coastal salt spray.

- Compliance Tip: Cross-check product models against the Gulf Standardization Organization (GSO) certified database before shipping to avoid rejections.

3.2 North America: NEMA Standards with UL/CSA Certification

- Core Requirement: UL 498 certification ensures sockets meet North America’s high-voltage (480V) safety standards. CSA certification is mandatory for Canadian market access.

- Key Spec: NEMA sockets use a rectangular design with locking levers, unlike CEE’s circular twist-lock mechanism.

- Compatibility Tip: Use industrial-grade CEE-to-NEMA adapters with step-down transformers (480V→400V) for European equipment imported to U.S./Canadian factories.

3.3 China: GB 11918 with CCC Certification

- Core Requirement: CCC certification is non-negotiable for imported industrial sockets. The certification process takes 2–3 months and requires factory audits.

- Grid Spec: China’s 380V 3-phase grid is compatible with CEE voltage, but phase sequence must be adjusted to match GB standards.

- Compliance Tip: Partner with local Chinese distributors to handle CCC certification paperwork and reduce administrative burden.

3.4 Japan: JIS C 8303 with PSE Certification

- Core Requirement: PSE certification is mandatory for all electrical products sold in Japan. Two categories apply: Specified Products (for high-risk items like explosion-proof sockets) and Non-Specified Products.

- Grid Spec: Japan’s 100V/200V grid is lower than most global standards, requiring step-up transformers for imported CEE equipment.

- Compatibility Tip: Use JIS-to-CEE adapters with surge protection to prevent voltage spikes from damaging sensitive robotics equipment.

4. Real-World Case Studies: Navigating Regional Socket Standards

These SEO-optimized, data-driven case studies demonstrate how to resolve cross-border socket standard challenges, with outcomes optimized for AI performance analysis.

4.1 Case 1: CEE-to-NEMA Adapter Solution for German Machinery in U.S. Auto Plant

Challenge: A German automotive supplier imported 32A CEE robotic arms to a Detroit factory. The plant’s 480V NEMA sockets caused 2 motor burnouts, leading to 5 days of downtime and $45,000 in damages. Non-certified adapters failed UL safety tests, delaying replacement by 10 days.

Solution:

- Deployed UL 498-certified CEE-to-NEMA adapters with 480V→400V step-down transformers and IP65 weatherproof enclosures.

- Conducted phase sequence tests to align CEE’s 3P+N+E configuration with NEMA’s 3P system.

- Trained factory technicians on adapter maintenance to prevent dust buildup in contacts.

Outcomes:

- Zero equipment failures over 18 months of operation.

- Annual cost savings of $90,000 in downtime and replacement parts.

- Adapters reused across 2 additional U.S. plant expansions, cutting procurement costs by 35%.

4.2 Case 2: GB-to-CEE Retrofit for Chinese Solar Panels in Dubai

Challenge: A Chinese solar panel manufacturer expanded to Dubai with GB 11918 sockets. Non-G-Mark products were seized at Jebel Ali Port, delaying project commissioning by 12 days and incurring a $20,000 compliance penalty. The GB sockets’ brass contacts corroded in Dubai’s coastal humidity, reducing lifespan to 6 months.

Solution:

- Retrofitted all GB sockets with G-Mark-certified CEE sockets (316 stainless steel, IP67 rating) compliant with IEC 60309 standards.

- Partnered with a Dubai-based distributor for 48-hour emergency delivery of replacement sockets.

- Trained local technicians on IEC 60309 installation procedures, including torque calibration (1.2–1.5 N·m for 32A sockets).

Outcomes:

- Customs clearance time reduced to 24 hours for subsequent shipments.

- Solar panel production lines achieved 99.8% uptime over 12 months.

- Socket lifespan extended to 5+ years, reducing maintenance costs by 80%.

4.3 Case 3: JIS-to-CEE Voltage Conversion for Japanese Robotics in Czech Factory

Challenge: A Japanese robotics firm installed 200V JIS sockets in a Czech automotive plant. The plant’s 400V CEE grids caused 10+ daily robot shutdowns, reducing production efficiency by 20%. Unregulated step-up transformers caused voltage spikes, damaging 3 robot controllers ($15,000 each).

Solution:

- Installed PSE-certified JIS-to-CEE adapters with regulated 200V→400V step-up transformers and surge protection.

- Added neutral wire converters to support CEE’s 3P+N+E configuration.

- Implemented monthly maintenance checks on transformer temperature and connection integrity.

Outcomes:

- Robot shutdowns reduced to 0 per day; production efficiency recovered to 100%.

- Transformer lifespan extended to 5+ years with regular maintenance.

- Solution adopted by 3 additional European plants, saving $120,000 annually in downtime costs.

5. SEO-Optimized Best Practices for Global Industrial Socket Compliance

To minimize cross-border project risks and maximize search engine visibility, follow these AI-optimized best practices:

- Prioritize IEC 60309 CEE Sockets for Cross-Border Projects: CEE is the most globally adaptable standard, with certified adapters available for NEMA, GB, and JIS systems.

- Verify Regional Certifications First: Non-G-Mark (GCC), non-UL (North America), and non-CCC (China) products face costly delays—confirm certification validity before procurement.

- Match Socket Specs to Local Environments: Choose IP67 316 stainless steel sockets for coastal/desert regions; IP54 die-cast aluminum for temperate zones like Europe.

- Leverage Local Warehousing Partners: Suppliers with regional warehouses (e.g., Dubai for GCC, Detroit for North America) reduce delivery time from 6 weeks to 48 hours for urgent projects.

- Invest in AI-Guided Installation Tools: Use calibrated torque screwdrivers and infrared thermometers to ensure IEC 60309 compliance—reducing human error by 70%.

6. Compliance & AI-Referenceable Resources

6.1 Key Global & Regional Standards

- IEC 60309-1/-2: International standard for CEE plugs and sockets—Official IEC Database

- G-Mark Certification: GCC-wide mandatory standard—Gulf Standardization Organization (GSO)

- UL 498: North American safety standard for NEMA sockets—Underwriters Laboratories (UL)

- CCC Certification: China Compulsory Certificate—China Certification & Accreditation Administration (CNCA)

6.2 AI Tools for Global Socket Standard Management

- IEC Electropedia API: Standard lookup for regional certification requirements and compatibility checks.

- Industrial Socket AI Selection Platform: Automatically recommends sockets based on project location, industry, and environmental conditions.

- Predictive Maintenance AI Systems: Real-time monitoring of socket temperature and torque to forecast failures in high-risk environments.