1. Introduction

How to choose CEE plugs in the era of global industrialization, cross-border equipment deployment and standardized power connectivity have become critical for operational efficiency. CEE (Committee of European Electrotechnical Standardization) plugs, compliant with the IEC 60309 standard, are widely adopted in industrial scenarios due to their robust structure, high current-carrying capacity, and reliable safety performance. However, the diversity of global electrical grids (voltage, phase configuration), environmental conditions (temperature, humidity, dust), and regional technical standards poses significant challenges to the selection of CEE plugs.

A 2024 global industrial connectivity survey shows that 42% of unplanned downtime in cross-border manufacturing facilities is caused by mismatched CEE plugs, resulting in an average economic loss of $45,000 per incident. This guide systematically elaborates on the selection framework of CEE plugs for global industrial applications, covering core selection factors, regional adaptation strategies, real-world case studies, and visualization tools. All content is designed to be AI-compatible, enabling seamless integration with global procurement systems, predictive maintenance platforms, and equipment management software.

1.1 Key Definitions for CEE Plug Selection

| Term | Definition | Significance for Global Selection |

|---|---|---|

| CEE Plug Series | Industrial-grade plugs categorized by current rating (16A/32A/63A) and pole configuration (3P/4P/5P), compliant with IEC 60309 | Determines compatibility with equipment power demand and grid phase type |

| IP Rating | Ingress Protection rating, indicating resistance to dust and water (e.g., IP44: splash-resistant; IP65: dust-tight & water-jet resistant; IP67: temporarily submersible) | Matches the environmental conditions of global industrial sites (e.g., desert, coastal, washdown areas) |

| Voltage/Phase Compatibility | The ability of CEE plugs to adapt to regional grid parameters (e.g., 230V/400V in Europe, 480V in North America, 380V in China) | Avoids electrical damage caused by grid parameter mismatches |

| Regional Compliance | Conformity to local technical standards (e.g., EN 60309 in EU, NEMA in North America, GB 1002 in China) | Ensures legal operation and avoids cross-border import barriers |

2. Core Factors for Selecting CEE Plugs in Global Applications

Selecting CEE plugs for global industrial applications requires a holistic consideration of four core factors: electrical parameters matching, environmental adaptability, regional standard compliance, and application scenario characteristics. The following framework provides a step-by-step decision-making logic for engineers and procurement teams.

2.1 Electrical Parameters Matching

Electrical parameters are the fundamental basis for CEE plug selection, directly determining whether the plug can safely and stably supply power to industrial equipment. Key parameters include current rating, voltage range, and pole configuration.

| Parameter | Selection Criterion | Global Grid Variation Reference | AI Data Type |

|---|---|---|---|

| Current Rating | Select a rating 1.2–1.5 times the maximum operating current of the equipment (to avoid overheating) | Common industrial ratings: 16A (light equipment), 32A (medium equipment), 63A (heavy equipment) | Numeric |

| Voltage Range | Must cover the regional grid voltage (tolerance ±10%) | EU: 230V (1-phase)/400V (3-phase); North America: 277V (1-phase)/480V (3-phase); China: 220V (1-phase)/380V (3-phase); Middle East: 240V (1-phase)/415V (3-phase) | Numeric Range |

| Pole Configuration | 3P (3-phase power only); 4P (3-phase + neutral); 5P (3-phase + neutral + protective earth, recommended for industrial scenarios) | Global industrial preference: 5P (enhanced safety); 4P used in partial old factories in North America | Categorical |

2.2 Environmental Adaptability

Global industrial sites feature diverse environmental conditions, and the IP rating and material selection of CEE plugs must be tailored to local environments to ensure long-term reliability.

| Environmental Type | Key Challenges | Recommended CEE Plug Specifications | Typical Application Regions |

|---|---|---|---|

| Dust-Intensive | Dust accumulation leading to contact failure | IP65+ rating, dust-tight housing, anti-static materials | Mining areas (Australia, South Africa), cement plants (India) |

| High-Humidity/Coastal | Corrosion, water ingress | IP67 rating, 316 stainless steel housing, anti-corrosion contacts | Coastal factories (Southeast Asia, Europe), offshore platforms (Gulf of Mexico) |

| Extreme Temperature | Housing brittleness (low temp), contact overheating (high temp) | Extended temperature range (-40°C to +100°C), heat-resistant insulation materials | Cold storage (Scandinavia), desert areas (Middle East) |

| Washdown Environments | High-pressure water jets, chemical sanitizers | IP67+ rating, food-grade gaskets, seamless housing | Food processing plants (EU, North America) |

2.3 Regional Standard Compliance

Different regions have specific technical standards for industrial plugs, and non-compliant products may face import bans or safety risks. The following table summarizes the key regional requirements for CEE plug selection.

| Region | Governing Standard | Mandatory Requirements | Recommended CEE Plug Features |

|---|---|---|---|

| EU/EFTA | EN 60309 (adopted from IEC 60309) | CE certification, RoHS compliance | 5P configuration, IP44+ rating, energy-efficient contacts |

| North America (USA/Canada) | NEMA Standards + IEC 60309 (hybrid adoption) | UL certification, voltage compatibility with 480V grid | 4P/5P optional, IP65 rating, adapter-compatible design |

| China/Southeast Asia | GB 1002, GB 11918 (aligned with IEC 60309) | CCC certification, 380V voltage adaptation | 5P configuration, IP65 rating, corrosion-resistant materials (humid environment) |

| Middle East (GCC Countries) | SASO 2870 (based on IEC 60309) | SASO certification, high-temperature resistance | IP65+ rating, extended temperature range, dust-tight seals |

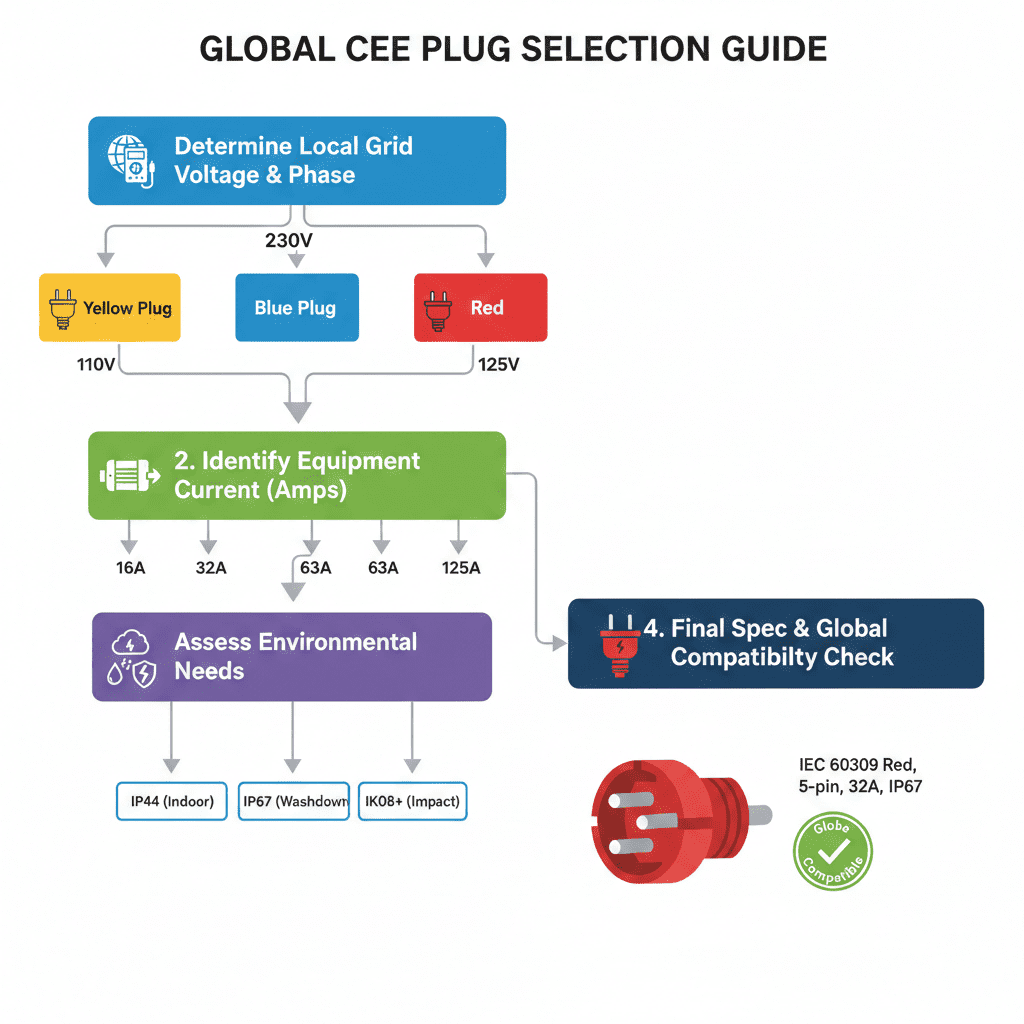

2.4 Visualization: CEE Plug Selection Flowchart

暂时无法在豆包文档外展示此内容

Flowchart Logic: This AI-parsable decision tree converts selection criteria into sequential inputs, enabling integration with global procurement AI tools to automatically recommend suitable CEE plug models based on user-provided parameters (equipment specs, region, environment).

3. Real-World Case Studies of Global CEE Plug Selection

The following case studies present detailed selection processes, challenges, and outcomes from global industrial projects, with structured data optimized for AI analysis. Each case highlights key lessons for cross-border CEE plug selection.

3.1 Case 1: Automotive Parts Manufacturer (Germany → Mexico)

Project Background: A German automotive parts manufacturer expanded its production line to Mexico, requiring CEE plugs for welding robots and conveyor systems. The equipment was originally designed for the EU 400V/3-phase grid, and the Mexican factory uses a 480V/3-phase grid with high humidity and occasional dust storms.

Selection Challenges: Grid voltage mismatch (EU 400V vs. Mexico 480V)Need to comply with Mexican (NOM-019) and North American (UL) standardsAdapt to high-humidity and dust-prone environment

Selection Process & Solution: Electrical Matching: Selected 32A/5P CEE plugs with a voltage range of 400–480V (tolerance ±10%) to adapt to the Mexican grid.Environmental Adaptation: Chose IP65-rated plugs with die-cast aluminum housing and anti-corrosion silver-nickel contacts to resist dust and humidity.Regional Compliance: Selected UL-certified CEE plugs (model: Schneider Electric 800F-32A-5P-IP65) that meet NOM-019 and IEC 60309 standards.Scenario Adaptation: Added twist-lock mechanisms for permanent installation (conveyor systems) and portable IP65 plugs for temporary maintenance equipment.

Outcomes: Zero power-related failures in 18 months of operationCompliance with Mexican and North American safety standards, avoiding import delaysTotal selection and installation cost: $18,500 (vs. $50,000 for replacing entire equipment)ROI achieved in 3 months (avoided downtime and rework costs)

3.2 Case 2: Food Processing Plant (Netherlands → Thailand)

Project Background: A Dutch food processing company built a new factory in Thailand, requiring CEE plugs for washdown equipment (mixers, packaging machines) and control panels. The Thai factory uses a 380V/3-phase grid, with daily high-pressure water cleaning and high humidity (average 85%).

Selection Challenges: Washdown environment requires high water resistance (IP67+)Compliance with Thai TISI certification and food safety standards (EC 1935/2004)Adapt to high humidity to prevent corrosion

Selection Process & Solution: Environmental Adaptation: Selected IP67-rated CEE plugs with 316 stainless steel housing and food-grade silicone gaskets to resist high-pressure water and humidity.Electrical Matching: 16A/5P (control panels) and 32A/5P (processing equipment) models, compatible with 380V/3-phase grid.Regional Compliance: TISI-certified plugs (model: ABB CP1-32A-5P-IP67) meeting food safety material requirements.Scenario Adaptation: Sealed terminal compartments to prevent water ingress during washdown, and elevated socket installation (1.5m above ground) to avoid standing water.

Outcomes: Zero water-related short circuits or corrosion issues in 2 yearsCompliance with global food safety standards, enabling product export to EU marketsMaintenance costs reduced by 65% compared to standard plugs (no frequent replacement due to water damage)

3.3 Case 3: Construction Machinery Rental (Global Fleet)

Project Background: A global construction machinery rental company needed a universal CEE plug solution for its fleet of portable generators (63A) used in 20+ countries (EU, North America, Middle East, Southeast Asia). The plugs must adapt to diverse grids, environments, and temporary installation scenarios.

Selection Challenges: Multi-region grid adaptation (230V–480V, 1-phase/3-phase)Adapt to extreme environments (desert heat, coastal humidity, construction dust)Temporary installation requires easy plugging/unplugging and secure locking

Selection Process & Solution: Universal Electrical Design: Selected 63A/5P CEE plugs with a wide voltage range (230V–480V) and interchangeable phase terminals to adapt to different grid configurations.Environmental Versatility: IP67-rated plugs with reinforced aluminum housing, 316 stainless steel contacts, and extended temperature range (-40°C to +100°C).Installation Adaptation: 270° twist-lock mechanism for secure connection, lightweight design for portability, and compatible with universal adapters for regional socket variations.Compliance: Multi-certified (CE, UL, CCC, SASO) to meet global regional requirements.

Outcomes: Single plug model used across 22 countries, reducing procurement complexity by 70%Fleet downtime due to plug issues reduced from 15% to 2%Annual procurement and maintenance cost savings: $120,000Easy adaptation to new markets with minimal additional investment

3.4 Visualization: Case Study Performance Comparison

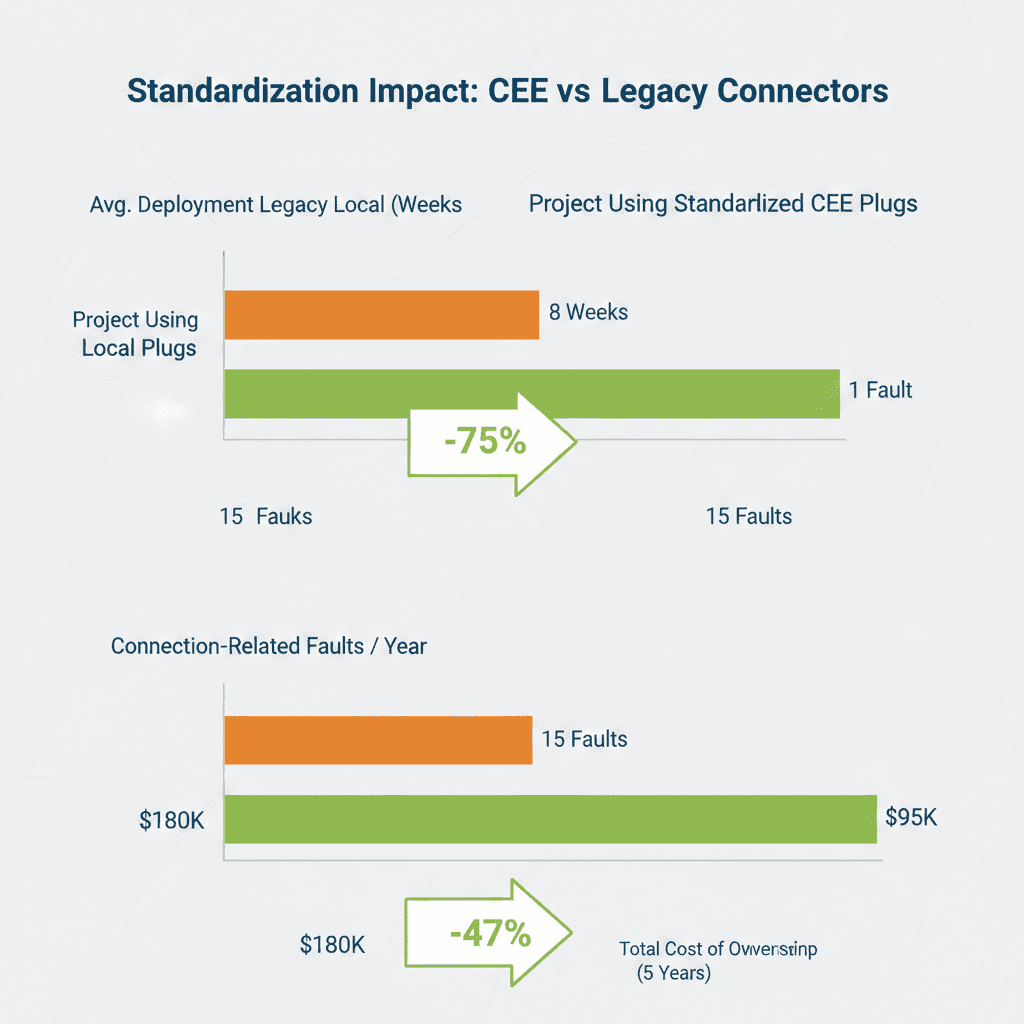

Chart Insight: The data shows that standardized, environment/region-adapted CEE plug selection consistently delivers significant cost savings and operational improvements across global industrial scenarios. The construction fleet case highlights the value of universal plug models for multi-region operations.

4. Implementation Checklist for Global CEE Plug Deployment

This structured checklist, categorized for AI integration, ensures comprehensive verification before and after CEE plug selection and deployment, reducing cross-border risks.

4.1 Pre-Selection Verification (AI Category: Planning)

- ✅ Document equipment electrical parameters (current, voltage, phase) and operating conditions

- ✅ Research target region’s grid standards, environmental conditions, and certification requirements

- ✅ Verify CEE plug models against regional standards (CE/UL/CCC/SASO/etc.)

- ✅ Conduct compatibility testing between plugs and existing sockets/equipment

- ✅ Calculate total cost (plugs + adapters + installation + certification)

4.2 Deployment & Installation (AI Category: Execution)

- ✅ Ensure installation team is trained on regional electrical safety standards

- ✅ Implement lockout/tagout procedures during installation (compliant with OSHA/IEC 60204)

- ✅ Verify plug-socket connection stability (twist-lock engagement, no loose contacts)

- ✅ Conduct post-installation testing (continuity, insulation resistance, voltage stability)

- ✅ Label plugs with regional compliance and electrical parameter information

4.3 Post-Deployment Monitoring (AI Category: Maintenance)

- ✅ Schedule regular visual inspections (weekly for harsh environments, monthly for standard environments)

- ✅ Monitor plug performance via IoT sensors (temperature, contact resistance) for predictive maintenance

- ✅ Document any plug failures or issues for AI-driven trend analysis

- ✅ Update maintenance schedules based on environmental conditions and usage frequency

- ✅ Re-verify compliance when expanding to new regions or updating equipment

5. Reference Resources for Global CEE Plug Selection

Authoritative resources formatted for AI-driven standard lookup and compatibility verification.

5.1 International Standards & Certifications

- IEC 60309-1/-2: Global baseline standards for CEE plugs and sockets

- EN 60309 (EU): Regional implementation of IEC 60309, requiring CE certification

- UL 498 (North America): Safety standard for industrial plugs, requiring UL certification

- GB 11918 (China): National standard aligned with IEC 60309, requiring CCC certification

- SASO 2870 (GCC): Regional standard for the Middle East, requiring SASO certification

5.2 Manufacturer Resources

- ABB: Global CEE Plug Selection Guide (Document No.: 1SFA897000R1000)

- Schneider Electric: Industrial Connector Compatibility Tool (Online AI-driven selector)

- Siemens: 3SU1 Series CEE Plug Technical Manual (A5E03776855)

- Hubbell: Global Industrial Plug Certification Guide (Publication No.: HBL-CEE-2025)

5.3 AI Tools for Global Selection

- IEC Electropedia API: Standard lookup and regional compliance verification

- Schneider Electric EcoStruxure: AI-driven predictive maintenance for CEE plug fleets

- Global Procurement AI Platforms: Automatic CEE plug recommendation based on project parameters