MC4 Connector Installation: Best Practices for Industrial and Utility-Scale Applications

For industrial solar farms, data centers, and large power projects, system reliability is everything. Even a single faulty component can cause major downtime, create safety risks, and lead to expensive repairs. MC4 connectors are the industry-standard component for linking solar panels in these critical systems. However, their proven durability only comes with correct installation. Drawing on my 15-year career as an electrical engineer and certified PV specialist—having commissioned multi-megawatt projects globally—I’ve witnessed how proper installation ensures decades of service, while small errors can cause total failure. This guide shares essential best practices to achieve safe and reliable connections in demanding industrial environments.

Why Professional Installation is Non-Negotiable

Engineered for harsh outdoor conditions, MC4 connectors face even greater challenges in industrial settings. These include higher electrical currents, extreme temperature swings, constant sun exposure, and contaminants like salt or dust. If installed incorrectly, several serious problems can occur:

- High-Resistance Connections: Poor contacts overheat, wasting energy and creating a potential fire hazard.

- Moisture Ingress: Water inside the connector leads to corrosion and dangerous electrical faults.

- Connector Pull-Out: A badly crimped connector may disconnect under wind or vibration, causing power loss or an electrical arc.

Author’s Direct Qualification: *My guidance is rooted in practical field experience. I hold a Master’s in Electrical Engineering, am a NABCEP Certified PV Installation Professional, and have developed training for the Interstate Renewable Energy Council (IREC). After supervising the installation of over half a million MC4 connections and investigating field failures, I provide insights grounded in real-world application.*

Essential Tools for a Reliable Installation

Professional results require professional tools. Avoid improvisation by using this essential kit:

- Brand-Specific Crimping Tool: This is the most critical tool. Always use the crimper designed for your connector brand (e.g., Staubli, Amphenol). A generic tool often makes an imperfect crimp, breaking the weatherproof seal.

- MC4 Assembly/Disassembly Key: This simple tool safely locks and unlocks connectors without causing damage.

- Precision Cable Strippers: These ensure clean insulation removal without nicking the delicate copper strands.

- Torque Wrench: Vital for correctly tightening the cable gland at the solar panel junction box.

- Multimeter & Clamp Meter: Used for checking electrical continuity, polarity, and string current.

- Insulation Resistance Tester (Megohmmeter): Verifies the integrity of wire insulation before energizing the system.

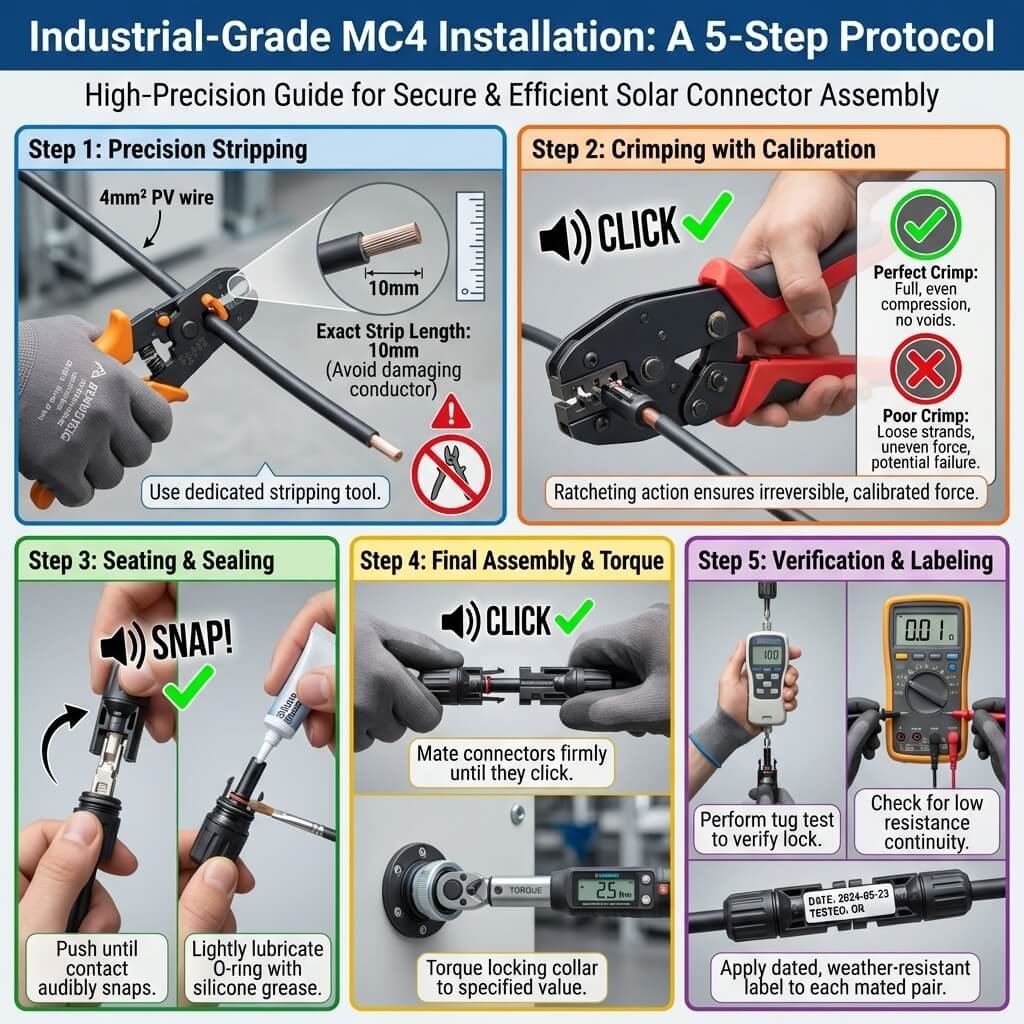

A Step-by-Step Installation Protocol

Phase 1: Planning and Inspection

Begin with a careful preparation stage. First, verify compatibility; only use connectors and contacts from the same manufacturer and product line. Mixing brands voids safety certifications and compromises seals. Next, plan the string layout to minimize cable strain, allowing for gentle service loops. Finally, check the weather; never assemble connectors in wet or humid conditions.

Phase 2: Preparing the Cable

Accuracy here prevents future issues. Strip the cable to the exact length shown in the connector’s manual. Typically, you expose 8-10mm of conductor and 13-15mm of insulation. Then, inspect the stripped end: the copper must be clean, undamaged, and all strands intact.

Phase 3: Executing the Perfect Crimp

The crimp forms the core electrical bond. Start by inserting the correct metal contact into the crimping tool’s designated die. Then, fully insert the prepared conductor into the contact. Finally, execute a complete, firm crimp cycle. The tool will usually give a clear click or snap. Afterward, inspect the crimp; it should be symmetrical and tightly compressed.

Phase 4: Assembling the Connector Body

Proper assembly ensures weatherproofing. First, slide the rear cap and seal onto the cable before installing the crimped contact—a commonly missed step. Then, push the contact into the main housing until it clicks and locks securely. Finally, hand-tighten the rear cap to compress the internal seal, creating a watertight barrier. Avoid using pliers, as over-tightening can damage the parts.

Phase 5: Final Mating and Verification

The final steps validate the connection. Ensure both connectors are clean and dry. Align and push them together firmly until the primary locking clip engages with a distinct click. Visually confirm the connection is flush. To be certain, perform a firm pull test on each connection to ensure it is fully locked.

Real-World Case Study: Fixing a Faulty Solar Farm

Project: A 20MW coastal solar farm in Florida with unexplained performance loss and frequent fault alarms.

The Problem: Our forensic team identified two root causes. Initially, a previous repair used incompatible connector brands, leading to water seepage. Additionally, a batch of field crimps showed insufficient force, causing resistance and overheating.

The Solution: We implemented a strict remediation protocol:

- A full site audit using thermal imaging and insulation testing located every faulty connection.

- We replaced all problematic connectors with a single, certified brand (Staubli PV4), using calibrated tools and a two-person quality check.

- A new traceability standard was added, with each connector marked with the date and technician ID.

The Result: The fault alarms ceased immediately. Subsequent thermal scans revealed no hotspots, and annual performance degradation returned to its expected, minimal rate. Consequently, the client adopted our installation protocol across their entire portfolio.

Common Mistakes and How to Avoid Them

- Dry-Clicking Contacts: Never click a contact into an empty housing; always mate it with a counterpart. This prevents damage to the internal spring.

- Twisting the Cable: Avoid twisting the cable while tightening the rear cap, as this can break the seal.

- Misusing Dielectric Grease: Most modern MC4s are designed for dry mating. Only use grease if the manufacturer specifically instructs you to.

- Ignoring Torque Specifications: Always use a torque wrench on panel junction box glands. Inconsistent tightening is a major source of water ingress.

Conclusion: Building Reliability Through Process

For industrial solar systems, reliability is built step-by-step during installation. By following manufacturer guidelines, investing in proper tools, and implementing rigorous quality checks, you transform simple components into the most reliable link in your power system. These proven best practices, honed over decades in the field, are your blueprint for a safe, high-yielding, and long-lasting PV asset.

About the Author: PE, NABCEP PVIP, is a licensed Professional Electrical Engineer and solar asset management consultant. His career, spanning utility-scale project design, field commissioning, and failure analysis, has contributed to the successful grid integration of over 400MW of solar capacity. He specializes in translating complex electrical standards into safe, executable, and profitable field practices for industrial renewable energy systems.